Grape sorting – The first step on the path to great wine

It is said that the story of a wine begins with the vine. The vine that the winemaker tends with care and respect throughout the year in the hope of a superlative result. It can happen, though, that this year-long effort is rendered vain in an instant if a raw material that utterly thwarts the desired objectives finds its way into grapes that are otherwise of good quality.

Grape sorting has long since ceased to be a winemaking fad and become a standard, in many cases essential, phase of wine production. The selection of grapes in the vineyard contributes to the integrity and health of the future wine, while through selection on reception it is possible to separate out damaged, rotten or unsuitable grapes (berries) and other “material other than grape” (MOG) which could affect the quality of the future wine.

Sorting harvested grapes, which is becoming a standard practice, can be done either manually or mechanically with a sorting belt conveyor. It has the direct effect of improving the raw material and thus represents the basis for producing wines of the highest quality. The processes used in winemaking are based above all on preserving the aromatic and other substances from the grapes. Sorting has a direct effect on improving quality. The sorting process separates healthy, ripe and compact berries from green parts (leaves, remains of stems), damaged, rotten or unripe berries, and juice that has leaked from damaged berries.

The purpose of sorting is to remove unwanted grape mass or particles before the start of the vinification process. Sorting can take place in the context of the selection of the vineyard, on the vine or after harvesting, in other words during processing. Sorting eliminates the following from wine production:

- oxygen-saturated juice that has leaked from damaged berries,

- poor-quality fruit: unripe clusters or clusters with a proportion of rot,

- other technologically undesirable material: branches and twigs, leaves, insects, slugs, caterpillars, etc.,

- selected grapes (berries) are kept and processed separately.

Much can be done to improve quality through the choice of grape harvesting method. Selection processes can already be carried out during the grape harvest, on the basis of the health and quality of the grapes and the characteristics of the vineyard:

- manual selection of grape clusters on the basis of visual characteristics

- manual harvesting of only specific parts of the cluster

- classification of grapes by quality with regard to specific parts of the vineyard

- selective harvesting in the same vineyard in different periods.

Manual selection of grapes

Manual selection of grapes in a vineyard on the basis of visual characteristics is the oldest selection technique. It is an accurate, relatively rapid and undemanding approach that requires visual inspection and the selective elimination of the whole cluster or just the unsuitable part. Accuracy is extremely important, particularly in the case of grape clusters with damaged berries infected with acidic or black rot. A significant proportion of these can cause infection of the must with fungal species such as Botrytis or Aspergillus, with acetic bacteria, and so on.

The removal of damaged grape berries can make a significant contribution to the quality of the future wine, since this helps reduce the formation of ochratoxin A. It is particularly important in the production of red wines or wines made using a maceration process. Grape berries infected with the mold Aspergillus carbonarius are the most common cause of ochratoxin A production. Even a brief contact of infected grapes with juice can be enough. Selection is an effective way of avoiding the problems associated with ochratoxin occurrence.

Guzev et al. (2006) found that grapes infected with Aspergillus mold contained 0.42 to 0.72 uM/L of ochratoxin A, while it could not be detected in clusters from which infected berries had been removed. This finding confirms the importance of sorting for the quality of future wine.

Harvesting only a specific part of a cluster can be done when the grapes are technologically ripe. Not all the grape berries in a bunch or cluster ripen homogeneously since there are always differences in sugar content, acidity, the proportion of secondary metabolites, the berry mass, the microclimate of the cluster, and so on.

Significant changes in the concentration of accumulated sugar and the proportion of anthocyanins take place in grape berries in the final days of ripening, although the concentration differs depending on the location of the part of the cluster. One study (Figueiredo-González et al., 2012) carried out 20 days before full ripeness found a higher proportion of sugar and a significantly lower (-33%) proportion of anthocyanins in the lower part of the cluster. By the time the grapes had reached full ripeness, the concentrations of the two parameters had equalized.

By choosing a suitable harvest time and harvesting only the lower parts of clusters, it is possible to pick, within the same vineyard, grape raw material that is suitable for specific types of wine. Grapes with higher acid content, lower sugar content and low anthocyanin content can be good material for sparkling wines or lighter rosés. The upper parts of the clusters can be left to ripen further and, because the clusters are smaller, the concentration of the products of photosynthesis will be greater at harvest.

Selective harvesting in individual parts of the vineyard is usually carried out in parts or sectors of a vineyard where the growth and development of the vines is the same. Increasing use is being made of multispectral techniques. With the help of light aircraft or satellite imaging, these create a map of the vineyard showing areas in which vines have the same developmental characteristics. The data thus collected can help the wine grower plan fertilisation and grapevine protection and inform the decision to harvest in a specific part of the vineyard.

Grape selection can also be carried out on reception of the grapes at the winery. Production of wines of the highest quality requires, in addition to carefully planned grape harvesting, an additional selection of clusters or berries before further processing takes place. The aim of this selection is to separate unripe, damaged or rotten berries and other organic material such as cap stems (pedicels), leaves, peduncles, and so on. Sorting gives the winemaker the opportunity to collect for further processing those grape berries that guarantee or enhance the potential to achieve the desired quality of wine.

Selecting grape berries is also important in the case of mechanical harvesting, where the quality of the picked berries differs because of the non-uniform development of individual clusters and differences in the ripeness and quality of individual berries. On reception of the grapes at the winery, a suitable selection strategy, where grapes are classified into different quality classes and wines are produced separately, can be helpful. Sorting is always carried out on the basis of the physical properties of clusters and berries, while the method and degree of selection must be adapted to the winemaker’s quality goals.

Choosing the right machinery

Sorting tables are used for manual selection, where workers positioned on either side of a vibrating table or conveyor belt separate those fruit that fall below the required quality. Sorting can involve whole clusters or individual berries following destemming, before the grape raw material continues on into the vinification process. Sorting berries has gained greatly in importance and has become an indispensable part of the production of high-quality wines.

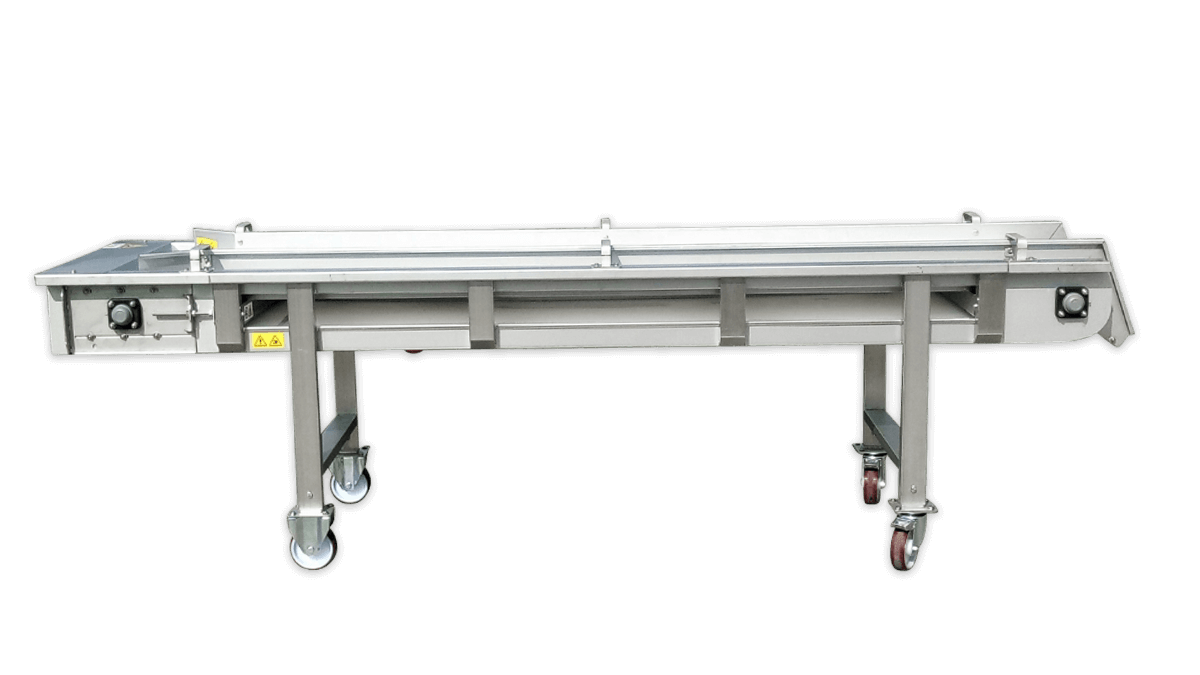

Sorting tables with PVC conveyor belt made by Sraml allow good distribution of grapes and good visibility, which is very important in manual selection.

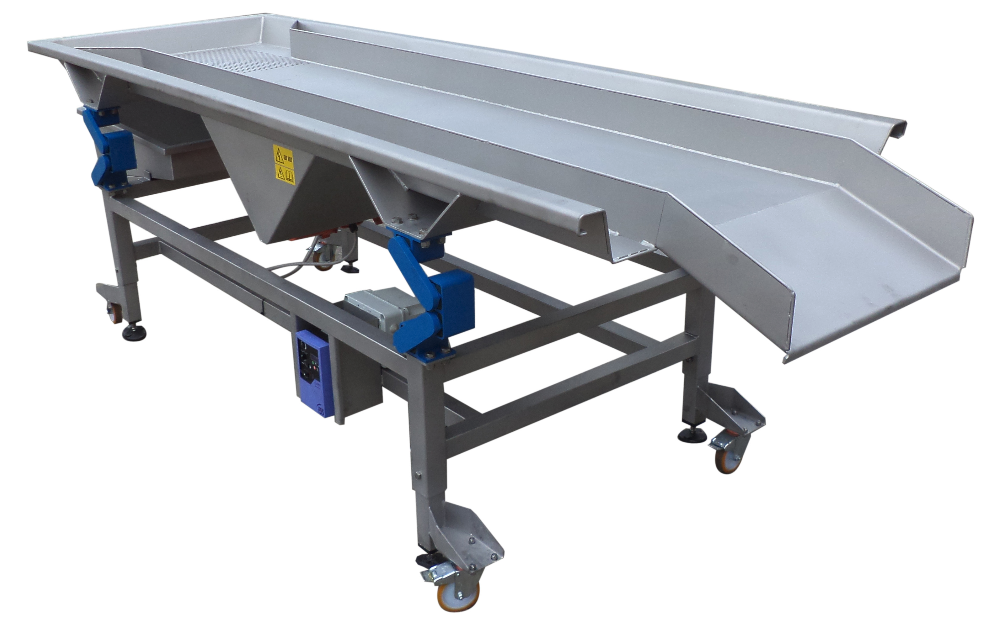

Sraml’s Vibrating sorting tables are made of stainless steel. The vibrating motion enables a uniform distribution and movement of grapes over the surface of the table. They are fitted with perforated sections enabling healthy and ripe grape berries to be kept separate from leaked juice, plant material and poor-quality berries. Both types of sorting tables must have variable operating speeds, since this enables control of the speed-to-efficiency ratio. The main disadvantage of sorting tables is the need for workforce to carry out the difficult separation of large numbers of berries.

TIP: As well as sorting, these tables ensure that grapes are uniformly dosed into the destemmer. Berries, skins, stems and seeds can be damaged if the destemming speed is too high and grapes are not dosed uniformly. Through intensive physical intervention, substances and juices that have a negative impact on final quality can be removed from parts of the cluster. Damage can be largely avoided by uniform and controlled dosing of the grape mass into the destemmer. Variable-speed sorting tables can be adapted to the optimal speed of operation, depending on technological equipment and the condition of the grapes.

Automatic sorting on the basis of berry compactness

Sorting grape berries after destemming is an important process that benefits quality. Whole and compact berries can be separated from damaged, soft and infected berries and other particles, usually the remains of stems. Conveyor-belt or vibrating sorting tables are most commonly used for this process. As well as moving the berries rectilinearly, these allow the drainage of leaked juice from damaged berries. A disadvantage of manual selection is the difficulty of sorting crushed and damaged berries.

Although the destemmer removes the great majority of stems and leaves, it cannot eliminate other unwanted small particles (trellis clips, splinters, bark, slugs, insects) or crushed, unripe, rotten, dry or disease-affected berries or leaked juice, etc. Even a small quantity of unsuitable grape raw material can have a negative effect on the further wine production process.

Recommendations issued to winemakers in Australia (Allan, 2004) show the percentages of unwanted substances (MOG) that can affect the quality of wine:

- Less than 1% – suitable for further processing.

- 1–2% – possibility of negative impact on wine quality.

- Greater than 3% – raw material not suitable for production of good-quality wines.

Automatic sorting tables

The functioning of automatic sorting tables is based on the physical characteristics of grape berries. Berry size and compactness are important properties that define healthy, undamaged and well-developed fruit.

Sraml’s sorting tables are fitted with a collection tank into which the berries fall directly from the destemmer. Although the destemmer functions very well, the destemmed mass can still contain oxidised must, remains of stems, damaged/rotten berries or other MOG not desirable in the production of high-quality wine.

Sorting tables consist of two sections: First section, with narrowly spaced sorting rollers: must, soft particles and smaller solid particles are separated between these. A separate tank with perforated double bottom is positioned below the rollers of the first section. The grape juice drains through the perforations, while damaged berries, skins, seeds and dry, undeveloped berries (raisins) collect on the mesh. A pipe can be fitted to the tank to allow the drained must to be collected separately. Particles that collect in the tank under the first section are simply emptied from the tank.

Healthy, compact berries and the remains of stems cannot fall through the gaps in the rollers in the first section and continue their journey to the second phase of sorting.

Second section with widely spaced sorting rollers: round berries of greater mass can fall between these and are then collected in a tank. Light, irregularly shaped stem particles are retained above the rollers and continue their journey towards the end of the sorting table, where they are ejected. Sorting is carried out in order to produce high-quality wines, where the retention of only undamaged, ripe and healthy grapes is a requirement.

At Sraml we have developed automatic sorting tables in order to make the sorting process efficient and accessible to all and contribute to the achievement of our common goal – even higher quality. We want our sorting tables to meet the requirements of all winemakers, which is why they can be adapted and fitted to existing destemmers.

The importance of keeping winemaking equipment clean probably goes without saying, since all of us are aware of the importance of cleanliness in ensuring the quality and integrity of wine. When designing our sorting tables, we followed the principle that cleaning them should be as rapid and effective as possible. The tables are fully washable and protected against water penetration. They can be washed with hot water or basic detergents. They are designed in such a way as to avoid openings, hidden edges and inaccessible areas where organic material could collect. The sorting rollers can be easily removed and washed separately.

When deciding to upgrade grape processing with a sorting system, it is important to keep in mind the following grape reception options:

- conveyor belt, where linear transport of grapes is necessary (reception of grapes on a sorting table, on a sorting table with destemmer or in a destemmer). A conveyor belt with a height setting is a useful tool that meets many transport needs in a winery. It must allow rapid, effective and simple cleaning.

- hopper – which must ensure compatibility between transport method and grape reception. The hopper must be designed in such a way as to prevent additional damage to grapes during reception and at the same time enable rapid reception. Hoppers can be designed to suit different methods of grape harvest and reception (reception of mechanically and manually picked grapes, reception on to a sorting table, reception into a destemmer and even reception of grapes into a press).

Grape sorting is today one of the so-called good practices of modern winemaking. It is also becoming increasingly important, since it allows the winemaker to eliminate particles that could have a negative effect on the overall quality of the wine. In the past sorting was mainly carried out by hand, but today sorting technology has become so accessible that there are practically no arguments against it. Sorting tables that adapt both to the grape variety and the method of work can contribute effectively to raising the quality of select wines and in this way ensuring that only the best is produced from our grapes, which after all is what we deserve.

Compiled by: Marko Benčina, BSc in Viticulture and Oenology

Images: Bruno /Germany, stephanfredthielen, Dieter Ludwig Scharnagl

Cover Image by Carlotta Silvestrini

Sraml d.o.o., 2021, all rights reserved

References:

- Allan, W. (2004). Winegrape assessment in the vineyard and at the winery. Adelaide, Australia.

- Reynolds G., A (2010). Managing wine quality. Volume 1: Viticulture and wine quality. Cambridge, United Kingdom.

- Parenti, A. et al. (2015). Comparison of grape harvesting and sorting methods on factors affecting the must quality. Licensee PAGEPress. Italy

- Nordestgaard, S. (2019). Latest advances in grape sorting technology. Grapegrower & Winemaker. Australia.

- Pregler, B. (2006). Product review: Manual Sorting Tables. Wine Business Monthly. https://www.winebusiness.com/wbm/?go=getArticle&dataId=43370, retrieved 3 January 2021

- Guzev, L. et al. (2006). Occurrence of ochratoxin A producing fungi in wine and table grapes in Israel. Int. J. Food Microbiology 111, S67–S71

- Figueiredo-González, M. (2012). Anthocyanins and flavanols berries from Vitis vinifera L. cv. Brancellao separately collected from two different positions within the cluster. Food Chem. 135, 47-56

- Morata, A. 2019. Red Wine Technology. Academic Press, United Kingdom