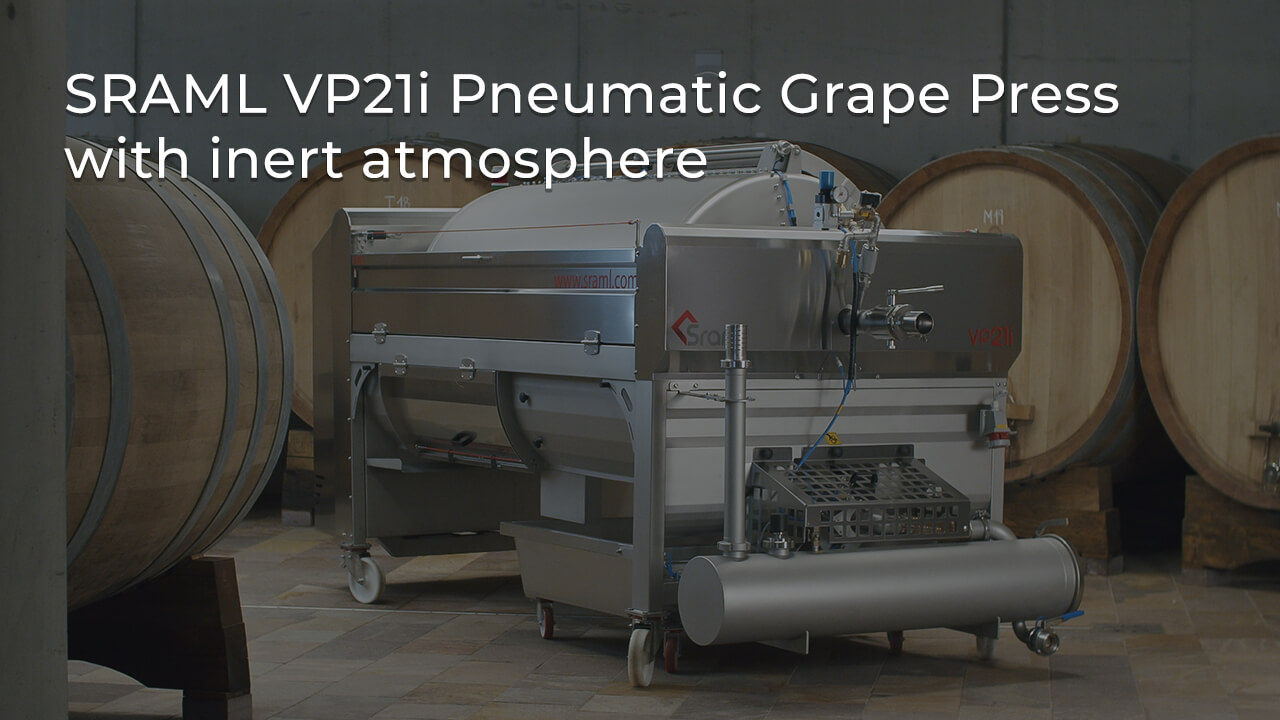

SRAML Food Processing Equipment Specialists

SRAML cutting-edge food processing technology provides fundamental support to all wine, juice and cider makers in pursuit of superior performance and product excellence.

About usSRAML Product Line

SRAML provides you with fully comprehensive fruit and vegetable processing lines, from grape presses, juice machinery to automatic filling and packaging lines.

Send inquirySraml TV

What makes us different?

Our success in numbers over the years. Let the numbers speak for themselves.

25

Years of experience

70

Countries

7,000

Satisfied customers

15,000

Machines sold