Grape harvesting and grape reception

Grape harvesting is one of the key tasks that present a challenge every year for all winemakers. Harvested grapes must be sent safely and in the shortest time possible for further processing, so as a general rule the harvest begins with outlining a detailed plan. We should make sure that the harvests are carried out efficiently and smoothly, taking into account – in addition to all professional guidance – experience with previous harvests and the use of appropriate winemaking equipment. We have thus prepared some professional advice to help you with planning and carrying out the harvest, and also with the following process of grape reception and processing.

When to plan the harvest?

Avoid harvesting grapes during the highest daily temperatures. Temperatures above 30°C may lead to hydrolysis of aromatic precursors and increase the risk of oxidation as a result of the action of enzymes called oxidases. The reception of warm grapes reduces their quality and value. Furthermore, it facilitates the development and action of undesirable microorganisms (yeasts, bacteria, molds), and cooling warm grapes requires a lot of energy.

The harvest should take place in appropriate weather conditions. We must not harvest grapes immediately after rain, as they would contain additional water that would dilute the must. Leave the grapes to dry for two to three hours after any rain.

Any possibility of damage or the harvesting of grape berries damaged by mold should be prevented, as it not only endangers the quality of the resulting wine but also poses a threat in terms of food safety. We have to remember that even the smallest damage will start the process of oxidation, so it is recommended to use smaller lugs for picking grapes.

Manual harvesting

Lugs for picking grapes should always be clean, without any juice, berry, or other organic material residues. Fast transport of grapes to a cellar and for further processing should be ensured, and waiting for the reception should be avoided (Sharma, 2013).

Transporting grapes to the cellar depends on the course and method of the harvesting work and organization of grape reception, and is often affected by technological conditions and economic factors. From a technological perspective, only cellar reception of healthy and undamaged grapes is allowed. The type of transport vessels selected should, to the greatest extent possible, preserve the physical and biochemical properties of grapes till the cellar reception. Grape berry contusions and crushing should be prevented by:

- using shallow containers (up to a height of 80 cm),

- using lugs without any sharp edges, made of easy-to-clean materials,

- reducing the number of grape movements (e. g. lug – dumper – transport trailer – receiving hopper) and dumping from high positions.

“To prevent any damage to grapes from the moment of picking onwards, only manual picking into small, perforated lugs is allowed in the wine-producing region of Champagne (France).” (Ribereau-Gayon et al., 2006).

Manual picking has several advantages that should be taken into account when making wine of superior and special quality. It is particularly recommended for all varieties with a thin and sensitive skin that gets easily damaged. Another benefit is that it makes it possible to select grapes in the vineyard, and thus pick only healthy grapes that are ripe enough.

Mechanical harvesting

Mechanical harvesting can deliver up to 75% lower harvesting costs in some wine-producing regions. The key advantage is the fast harvesting of grapes of optimal technological ripeness. Market pressures, vine training systems, and terrain topographies still require manual picking, but most vineyard surfaces in the old and new world are harvested mechanically. Mechanical harvesting is especially recommended at night when the grape temperature is low.

“Using modern technologies puts mechanical and manual harvesting in a technologically equivalent position. In particular, it is important to keep the grape berries undamaged and grape mass cold, and to make sure the grapes are transported to the cellar as quickly as possible.” (S. Jackson, 2014).

Most of the issues and deficiencies concerning mechanical harvesting are related to the damage caused to grape berries and uncontrolled quantities of discharged juice, transport duration and grape mass heating.

Studies (Pezzi et al., 2008) demonstrated that fast transport plays the most important role when it comes to the quality of mechanically harvested grapes, in terms of avoiding oxidation of grapes that have already been significantly damaged. Oxidation may be partly slowed down by adding sulphur dioxide and ascorbic acid and appropriate cooling.

Grape reception

When receiving grapes to the cellar, there are many loads of large masses. Numerous vehicles and moving parts pose a great hazard in a working environment, which is why the safety of the winemaker and their crew is a priority. Grape reception machinery must ensure safe work, decrease the winemaker’s physical effort and ensure the expected processing capacity.

Numerous vehicles and moving parts pose a great hazard in a working environment, which is why the safety of the winemaker and their crew is a priority.

The grape reception stage is of paramount importance for the quality of the future wine. Particular attention should be paid to not waiting with the processing and to start processing and cooling the delivered grapes as soon as possible.

A case study: The impact of grape reception on the quality of wine

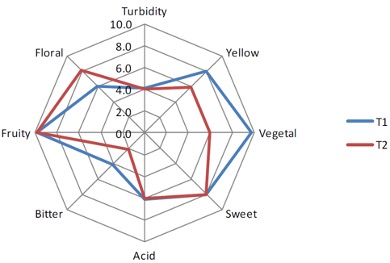

Grape reception should be adapted in a way so as not to cause any additional damage to grapes. In an experiment carried out at Palermo University (Catania et., 2016), two methods of processing the Chardonnay grape variety were tested.

They compared: T1 – the use of a transporter with a screw combined with a destemmer with blades without a rubber lining. The results of the study confirmed the differences in organoleptic and chemical parameters of the resulting must and wine, and demonstrated that the grape-reception method has impact on the quality of the wine made. T2 – the use of a conveyor belt and a destemmer with rubber lined rotor blades. The T1 (a transporter with a screw, destemmer with blades without rubber lining) test of the free-run juice during the grape-mass pressing stage showed 220 NTUs of suspended particles compared to 182 NTUs determined in the T2 (a conveyor belt and destemmer with rubber lined blades) analysis of the free-run juice. It is also interesting that the T1 test showed a lower concentration of total polyphenols, which was probably caused by skin grinding resulting in oxidation.

| Sugars [g/L] | Juice density | Total acidity [g/L] | Volatile acids [g/L] | Total polyphenols [g/L] | |

| T1 | 1.38±0.06 | 0.913±0.004 | 6.9±0.07 | 0.21±0.02 | 248±6.51 |

| T2 | 1.8±0.04 | 0.912±0.01 | 6.27±0.1 | 0.20±0.02 | 263±6.11 |

The sensory analysis confirmed the differences between the wine samples tested with a 95% confidence level. The wines from the T1 test were much yellower as a result of oxidation due to skin damage, and fruity odours were dominated by ‘green’ odours. Furthermore, the wines from the T1 test were more bitter due to damaged grape skins and lignin extracted from the stems.

Reception of manually picked grapes to crates and containers

The cellar reception of manually picked grapes mostly involves crates, containers, tractor trailers with load bins or specially adapted trailers for grape transport. Šraml develops reception solutions.

The GBE conveyor belt

The Grape Belt Elevator conveyor belt is equipped with a wide receiving hopper for discharging picked grapes into crates or containers. We also recommend it as a solution for receiving picked grapes to adapted harvesting trailers. The bottom of the receiving hopper is perforated, allowing must to be drained.

Grape transport by the GBE conveyor belt does not cause additional damage to grapes, at the same time allowing additional selection of the grapes received. It can be used for transport at different angles, lengths or heights. The conveyor belt is also equipped with a release mechanism enabling easy cleaning of both conveyor-belt surfaces after use. A CIP procedure can also be carried out.

A wheeled support frame enables the conveyor belt to be easily moved and used for various purposes (transporting grapes, fermented mass, marc, etc.).

The term ‘Cleaning in Place’ (CIP) refers to the use of chemical agents, heat and water for washing machines, vessels and pipelines in the food and pharmaceutical industry. When processing food, attention should be paid to a clean environment and equipment, as the quality of the food produced is based on hygiene. The advantage of CIP is that no dismantling or opening of the equipment is required. When carrying out the CIP procedure, appropriate equipment will be of great help. The main advantages of CIP are:

- less effort and work needed for cleaning

- better cleaning control.

- equipment designed for ensuring hygiene standards,

- the CIP system must have appropriate dimensions and must ensure a sufficient liquid flow rate and pressure.

- The CIP procedure must be carried out by a responsible and qualified person.

A successful CIP procedure requires the following:

The CIP procedure requires physical, thermal or chemical energy to remove residues and impurities from vessels and equipment. Physical energy enters the process by means of a cleaning liquid moving in a pressure-driven turbulent flow and cleaning internal equipment surfaces.

The correct CIP procedure sequence is also important:

- Rinsing with water – removing sediments and larger impurities by rinsing vessels or cellaring equipment (5 minutes)

- Cleaning with a base – dissolving and removing organic material sticking to vessel or equipment walls (20 minutes)

- Rinsing with water – removing the base and dissolved organic matter residues (5 minutes)

- Cleaning with an acid – mostly with citric acid. Rinsing with an acid neutralises the effect of the alkaline detergent and minerals (20 minutes)

- Re-rinsing with water – to eliminate acid detergent residues (5 minutes).

JK container tipper

Harvesting grapes into containers enables the grape berries to remain whole and reduces the possibility of the grapes being damaged or pressed down during transportation. Containers allow for higher quantities of grapes to be transported at once, as well as easy and fast cleaning after use.

Harvesting grapes into containers is a demanding task in terms of grape reception, as the containers are usually heavy and challenging to empty. A full container can be installed in the JK tipper by a pallet truck or a forklift and tipped in a controlled manner by an installed hydraulic mechanism to the height of a collection hopper, conveyor belt or sorting table. A cone-shaped outlet enables precise dosing of grapes and prevents scattering.

With the JK tipper, containers with loads of up to 500kg can be tipped. It is designed without any sharp edges, and the hydraulic system allows for the precise and gentle transfer of the load.

Receiving grapes from transport trailers and mechanically harvested grapes

Receiving grapes loaded onto transport trailers is a demanding task, as the load comes in the form of a compact mass with plenty of drained juice due to a higher content of grapes damaged during the transportation. The reception must allow for the receipt of a large mass of grapes at once, and at the same time prevent any juice spillage.

Mechanically harvested grapes come in the form of a liquid mass with plenty of organic material, and are delivered to cellars mostly in specially adapted transport or container trailers. Trailers are adapted for emptying by means of a side hydraulic elevation or a screw installed at the bottom of the transport trailer. Due to the liquid state of the load, particular attention should be paid upon reception, especially when the load is received by hydraulically elevating the load bin. Šraml offers also solutions for such demanding jobs.

Receiving hopper with a transport screw

Provides a safe and efficient method for receiving compact and liquid loads. Due to its large collection area and volume, loads can be transferred by hydraulic elevation. Grape hopper’s bottom is equipped with a transport screw that moves compact grapes towards the outlet to the next processing stage (destemmer, sorting table, conveyor belt).

The flow rate of a liquid, mechanically harvested grape mass is controlled by hydraulically closing the door on the receiving hopper’s outlet. Large quantities of liquid mass could flood the inside of the grape destemmer, which would lead to significant losses and leakage. When receiving mechanically harvested grapes, we recommend the destemmer be upgraded with a grape juice draining unit. By draining the grape juice is rerouted directly to a pump, whilst berries are separated from the stems and other material into the destemmer’s bin and collected in the hopper.

Transport and reception of manually or mechanically harvested grapes is the first winemaking stage, and has a significant impact on the quality of the resulting wine. Although it depends on the technological requirements and organizational capabilities of individual winemakers, attention should be paid to preserving the quality of grapes during transport and reception. Furthermore, the grapes harvested should be kept as cold as possible. As grape reception involves large-mass loads, the best way to ensure safe work is to use appropriate equipment. This is of paramount importance for the quality of new wine.

Compiled by: Marko Benčina, BSc in Viticulture and Oenology

Images: Sraml Archive, jacqueline macou, missclick and richarem

Cover Image by Jill Wellington

Sraml d.o.o., 2021, all rights reserved