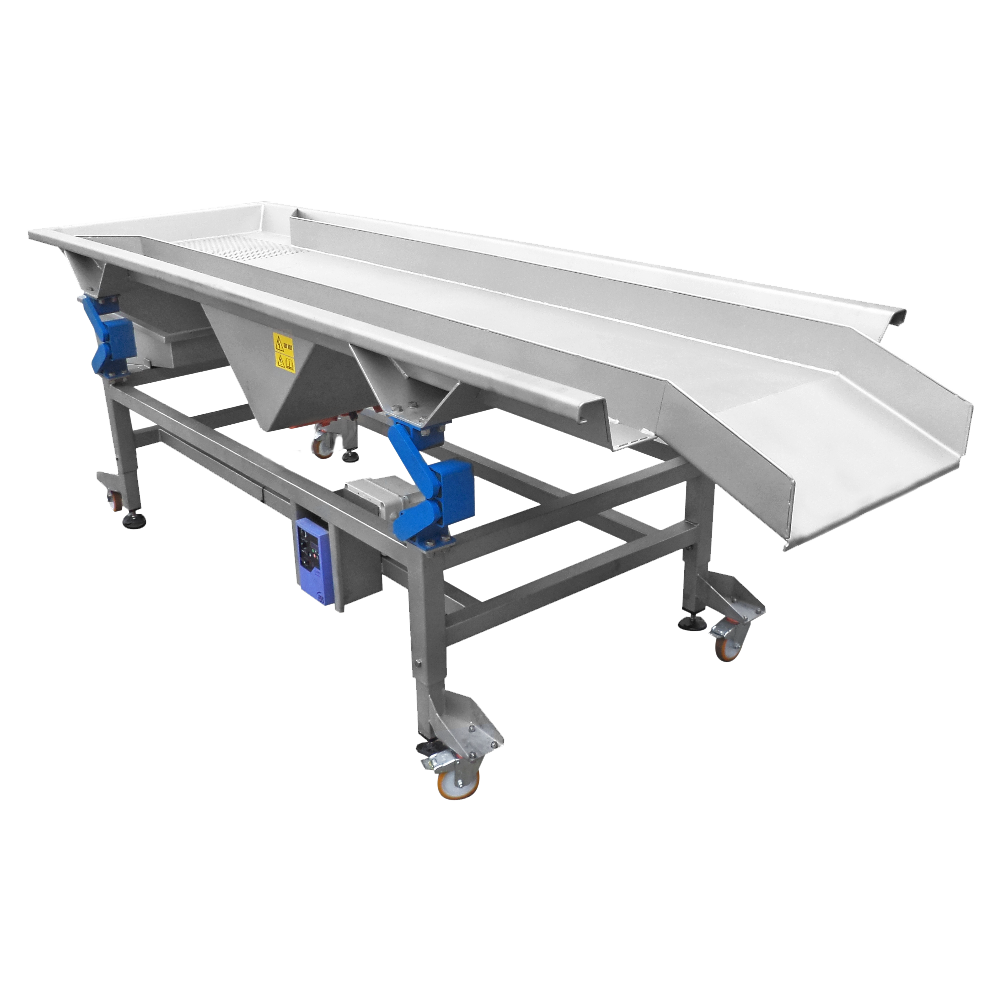

Vibrating sorting tables

Vibrating motion generates a gentle and smooth grape flow, keeping berries intact, and allows for careful visual inspection only to leave ripe grapes that are in perfect condition.

The SRAML VT range of vibrating sorting tables enables efficient manual sorting and removal of whole or destemmed poor-quality grapes and unripe bunches, whether manual or machine-picked. Gentle transportation by means of a vibrating motion protects the berries from damage and allows for careful visual inspection to leave only the grapes that are in perfect condition in order for you to meet production targets.

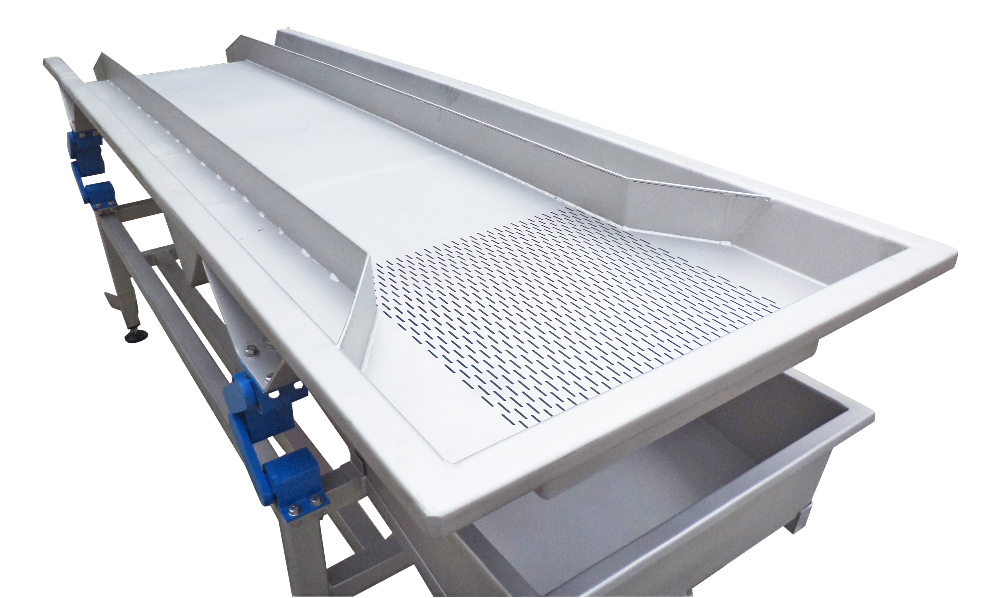

- Central channel for grapes of desired quality

- Two lateral channels for conveying the waste

- Juice drainage grid and juice collection tank beneath the table

- Transportation accomplished by a vibrating motion

- Frequency regulator for speed control on the central command box

- Support legs on braked swivel casters

- Available in different width and length

Product specifications

- Transportation is accomplished by a vibrating motion

- Central channel for the grapes and two lateral channels for conveying the waste

- Juice drainage grid and juice collection tank

- Frequency regulator for speed control on the central command box

- Hopper of 1,500mm x 1,500mm. Supply from the bins directly onto the conveyor.

- 2nd screen for draining

| Name |

|---|

| VT 3000 × 800 |

| VT 4000 × 800 |