Pome fruit processing technology

With a core of several small seeds surrounded by a tough membrane, apples, pears, nashi and quince are processed into a variety of products, but one of the most common, by far, is pressed fruit juice with the largest volume of processed pome fruits — apples, in particular. Apple and pear juice can take on many forms, including a natural-style cloudy juice, a nectar containing suspended solids and clarified juice.

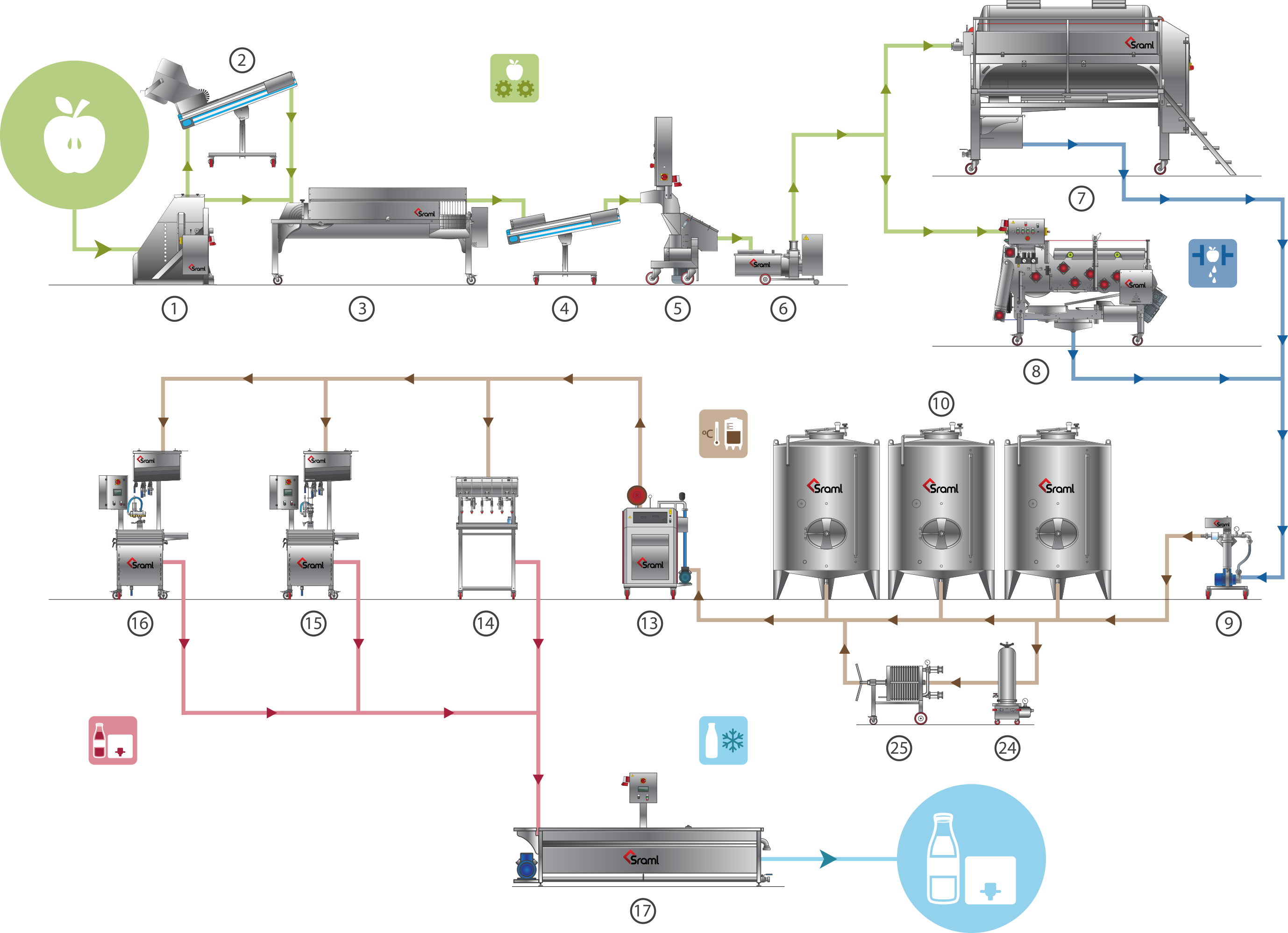

SRAML R&D team designs a product-specific solution adapted to each pome fruit product and its method of sorting, washing, grinding, extraction, preservation and packaging.

Whether you opt for individual or complete juice machinery to make pome fruit juice or pome fruit purée, or request a mobile processing line, our in-house R&D expert team will help you select just the equipment you need and work with you on project planning to develop the best solution for your business.