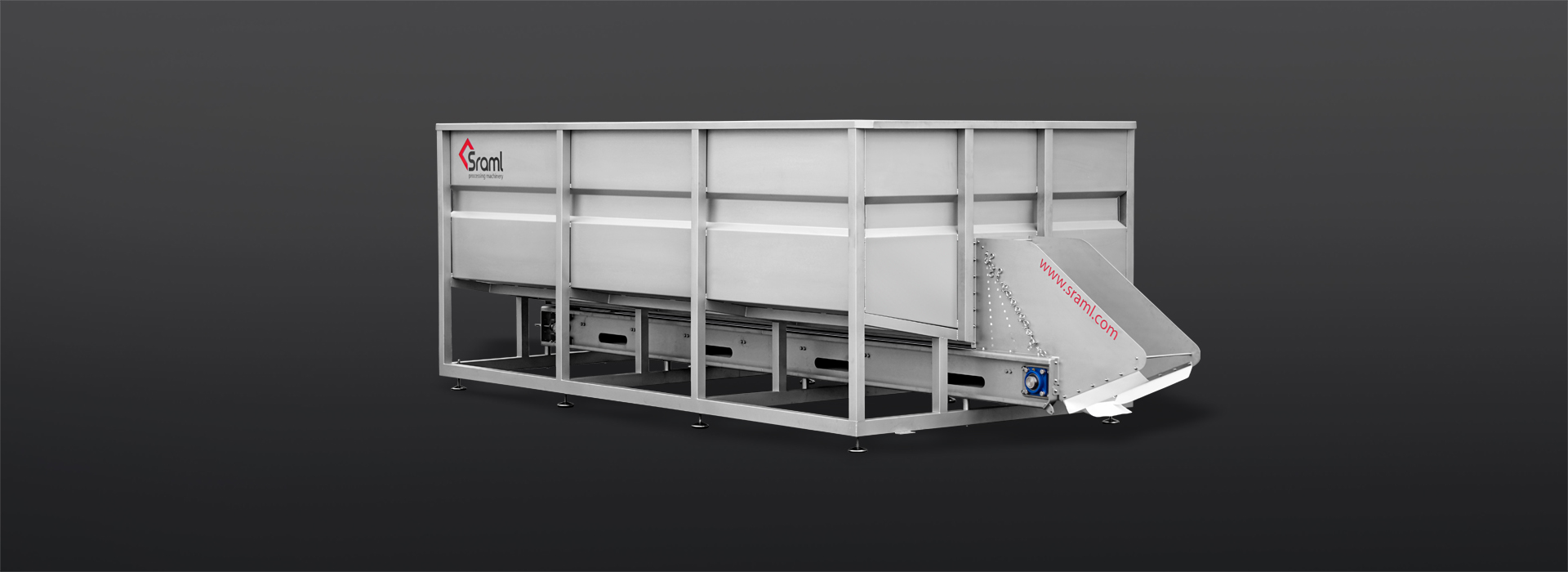

Bin tipper

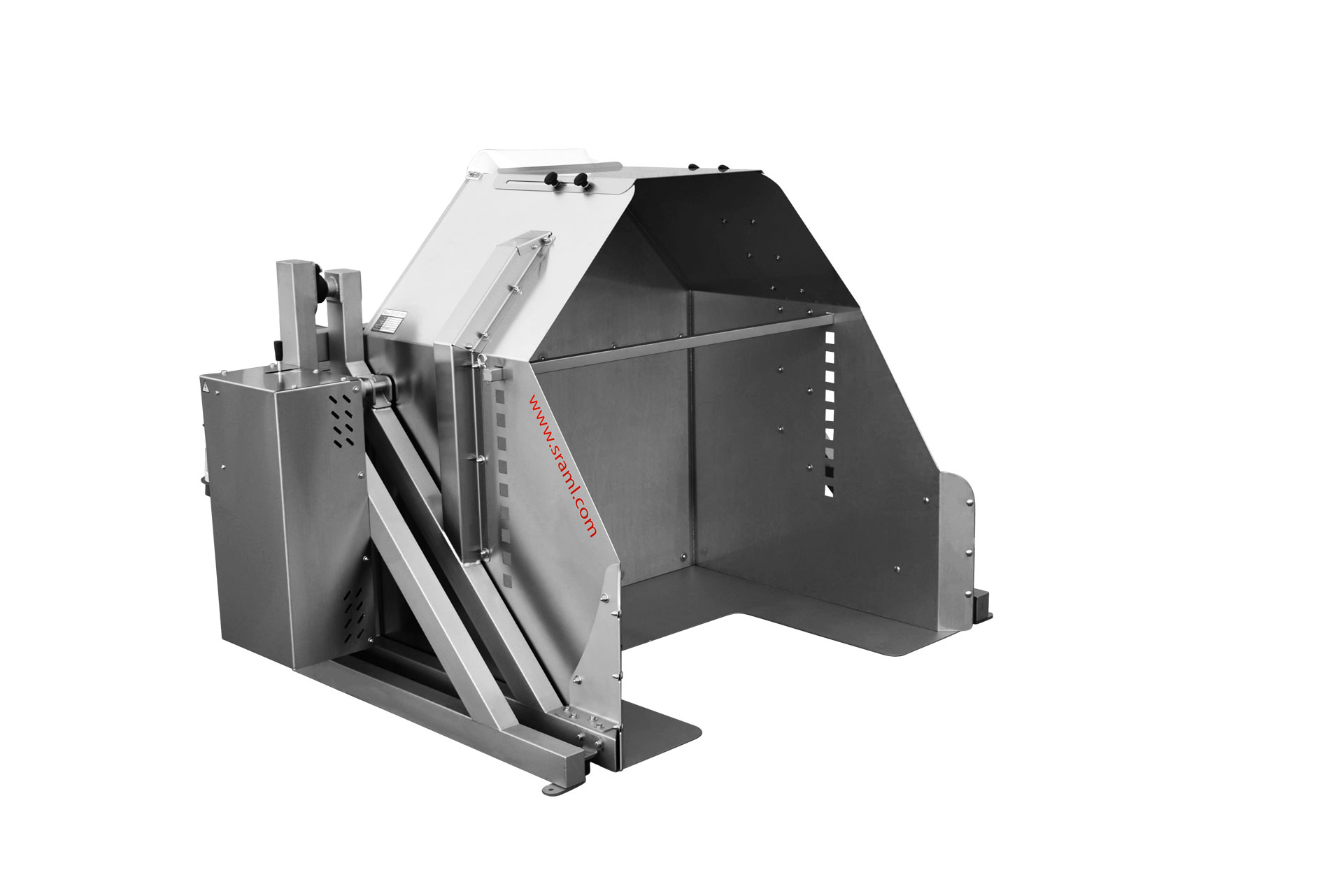

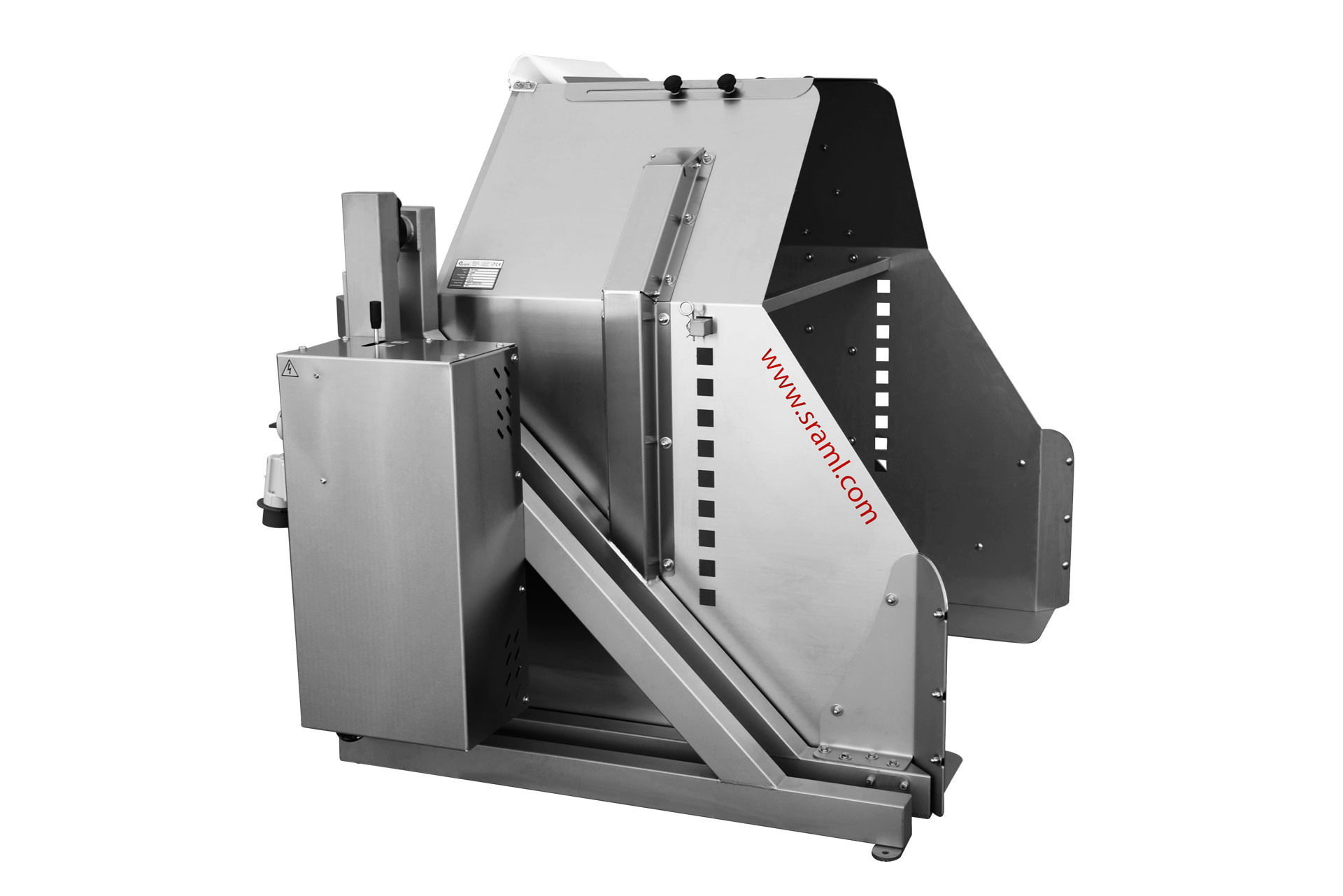

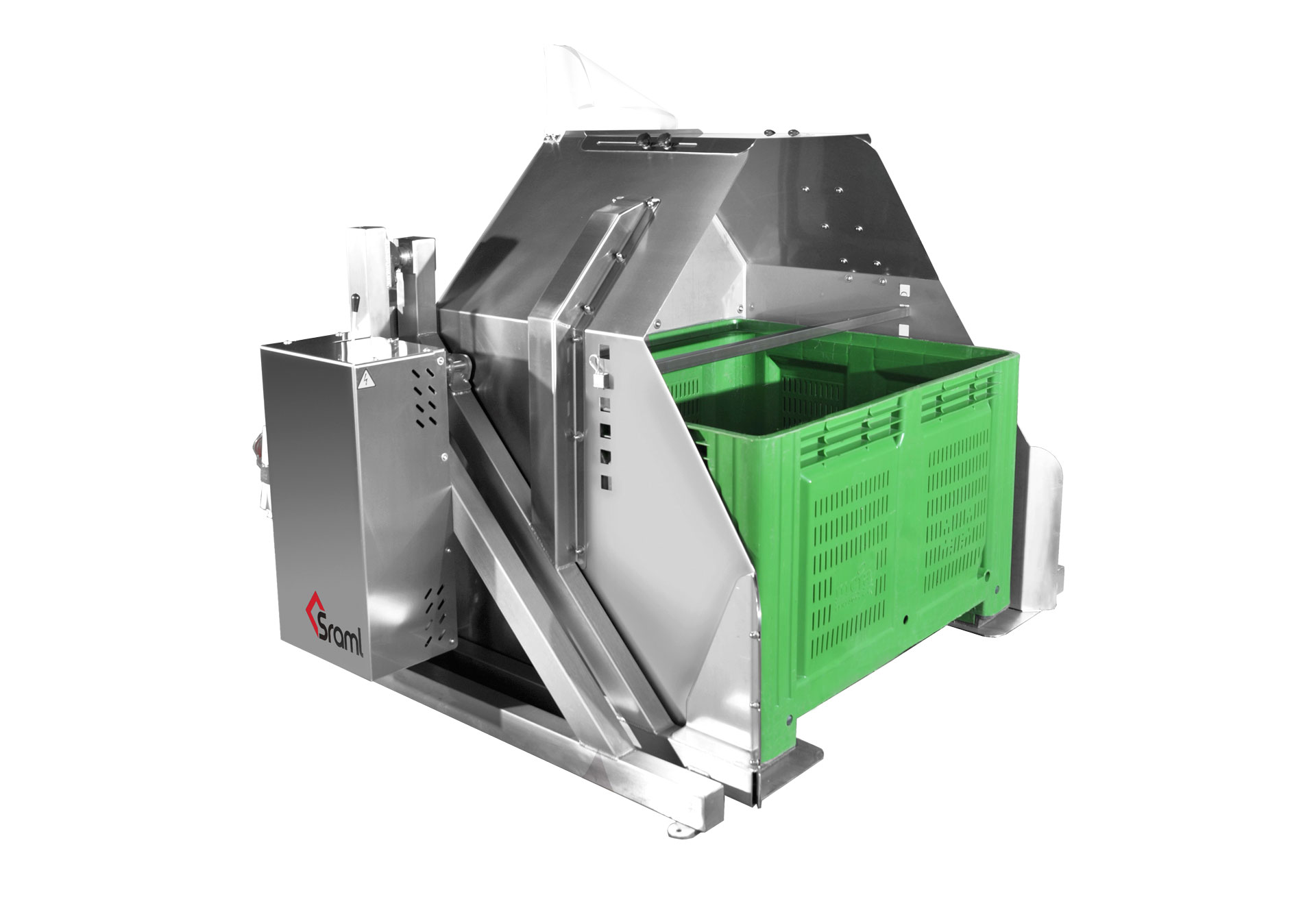

The bin tipper or tipping unit mechanically lifts and inverts harvest bins, which are transported by a forklift, to unload the grapes into a reception hopper for further processing.

Hydraulic Bin Tipper JK from SRAML efficiently empties various-sized harvest bins into the reception hopper, feeding the grapes onto the conveyor belt for further processing.

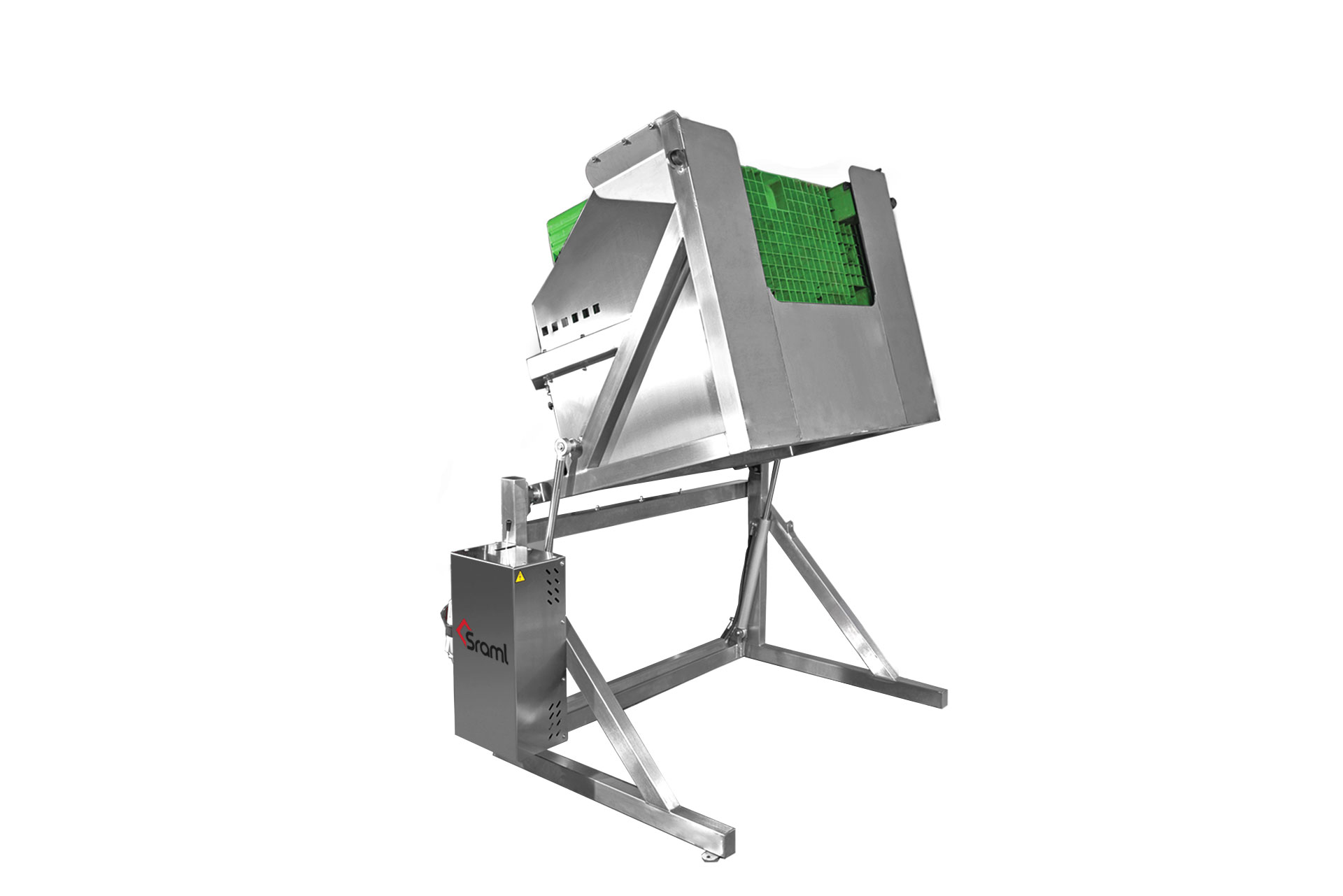

Once a full bin of fruit is loaded onto the bin tipper’s tipping cradle, the operator starts the tipping motion. Hydraulic lifting cylinders lift and invert the steel bin, directing the grapes through the adjustable flow gate towards the hopper of the conveyor that follows.

Our hydraulic bin tippers are floor mounted and designed in a way that minimizes drop height and optimizes gentle tipping. The bin tipper’s durable and robust construction makes sure that the machinery withstands the burdens of lifting heavy bins and possible forklift knocks.

SRAML tipper bins features include:

- Adapted to different bin sizes

- Hydraulic lifting cylinders lift, invert and empty the harvest bin

- Grapes are directed to an adjustable flow gate towards the hopper of the conveyor that follows

SEND INQUIRY

Product specifications

- Stainless steel construction with hydraulic lifting cylinders

- Hydraulic unit with protective cover

- Adjustable gate to regulate the fruit flow quantity

- Operating handle to control the tipping motion

- Height-adjustable bin retaining bracket to prevent the bin from falling out

- Bin tipper on swivel casters

- Higher bin tipper + 300 mm

- Machine with different electrical supply

- Solenoid control valve

| Name |

|---|

| Bin tipper JK500 |

| Bin tipper JK500H |

| Bin tipper JK500W |