VP Eco Pneumatic Presses

Best suited for boutique to mid-sized wineries, the SRAML VPe— Eco Pneumatic Membrane Press series combines the simplicity of design and use with innovation for the ultimate performance.

Equipped with a number of programmable pressing cycles and improved drain surface to maximise juice yields, the SRAML VPe line is the ultimate addition to your winery. Gentle pressing of the grape mass and significant reduction of processing time is key to achieve the quality of wine you have been aiming for.

Available in sizes from 500 L to 6000 L, the plug-and-play VPe series stands for user-friendly operation and best price-performance ratio, offering a vast array of upgrade possibilities to create the ideal press for your production demands.

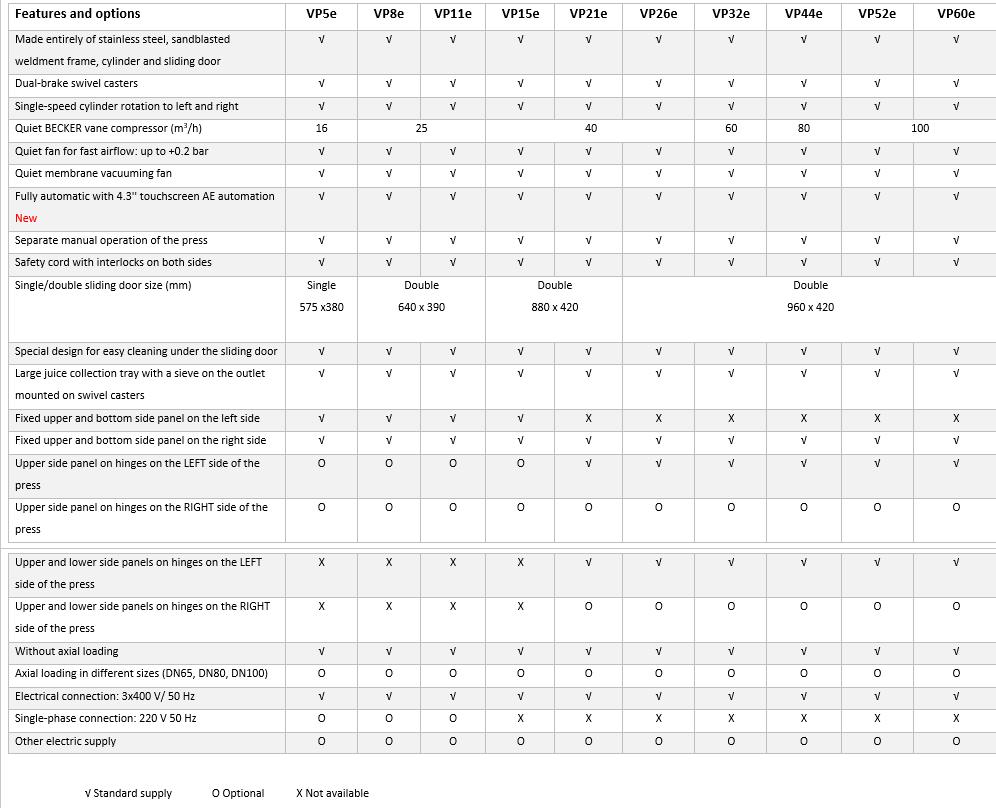

VPe Eco Pneumatic Press features include:

- User-friendly PLC touchscreen control with 12 pre-programmed pressing cycles

- Additional 8 channels for individual programming

- Built-in fan for rapid inflation at low pressure

- Ultra-quiet Becker compressor for high-pressure pressing

- Large mobile juice collection tray with sieve on the outlet

- Large double sliding door to provide easy interior access for loading, unloading and cleaning

- Open or closed-cage pressing system

- Hygienic design

- Available in sizes from 500 L to 6000 L

Product specifications

- Made entirely of stainless steel

- Dual-brake swivel casters

- Cylinder rotation to both sides: left–right

- Mirror-polished drainage channels

- Quiet BECKER vane compressor

- Quiet fan for fast airflow: up to +0,2 bar

- Quiet fan to vacuum the membrane

- AE automation with touch screen

- Separate manual operation of the press

- Safety cord with interlocks on both sides

- Hygienic design for easy cleaning under the sliding doors

- Large juice collection tray with a sieve on the outlet mounted on swivel casters

- VP21e, VP26e, VP32e, VP44e: Upper and lower sides on hinges on one side of the press

- Declaration of Conformity (CE marking)

- PED documentation

- Without axial loading (optional)

Automation control

- Automatic AT (7” touchscreen)

- Collection tank level switch

- Smart speed control and soft cylinder rotation

- Cord or radio remote control

- Grape mass weighing system

- Separate electric box with display

- Acoustic alarm on axial loading and automatic stop for external pump with axial loading

- Monophasic connection or different electrical supply

Axial loading

- Axial loading ball or pinch valve

- Sight glass for mass flow monitoring

Cylinder

- Non-perforated door for maceration

- Plugs to seal drain channel outlets

- Large opening for cleaning purposes

- Drainage channels on the hinges

- Watertight double sliding door with inflatable seal on the cylinder

- Pneumatic door open–close mechanism

- Central juice outlet (installed INSIDE the drum)

- Central juice outlet (installed OUTSIDE the cylinder)

- Double jacket on the cylinder — not insulated — for cooling/heating purposes

- Net for apple pressing

Frame

- Elevated press

- Staircase platform by the press

- Different side panel opening and closing options

- Motorized movement of the press

- Drawbar for moving the press

- Fixed sink with the sliding tray

Cleaning

- Cylinder external washing

- Manual interior cleaning of drain juice channels and a sewer with high-pressure washer

- Automatic interior cleaning of drain juice channels and a sewer with high-pressure washer

- Automatic PULSE (water–air) drain channel cleaning

Loading hoppers

- Loading hopper

- Loading hopper with crusher

- Loading hopper mounted on a stand-alone trolley

- Loading hopper with crusher mounted on a stand-alone trolley

| Name |

|---|

| VP5e |

| VP8e |

| VP11e |

| VP15e |

| VP21e |

| VP26e |

| VP32e |

| VP44e |

| VP52e |

| VP60e |

| Cylinder volume Vc (L) | Length x Width (door) L x W (mm) | Sink diameter Ds (Ø) | Sink volume Vs (L) | Length with axial loading Lcp (option) (mm) | L (mm) | W (mm) | H (mm) | Marc discharge height Hc (mm) | Power supply with integrated compressor (kW) | Dry weight (kg) | Whole grapes – loading through door (kg) | Fresh destemmed grapes – axial loading (kg) | Fermented grapes – axial loading (kg) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 500 | 575 x 380 | 1" | 230 | 2130 | 1960 | 1040 | 1390 | 450 | 2,5 | 290 | 275-390 | 925-1260 | 1300-1750 | |

| 800 | 640 x 390 | 1" | 360 | 2410 | 2240 | 1140 | 1480 | 470 | 2,8 | 340 | 440-624 | 1480-2016 | 2080-2800 | |

| 1100 | 640 x 420 | 1" | 450 | 2520 | 2350 | 1270 | 1560 | 490 | 3 | 490 | 605-858 | 2035-2772 | 2860-3850 | |

| 1500 | 880 x 420 | 1¼" | 580 | 3020 | 2850 | 1270 | 1560 | 490 | 4,4 | 620 | 825-1170 | 2775-3780 | 3900-5250 | |

| 2100 | 880 x 430 | 1¼" | 710 | 3120 | 2950 | 1470 | 1790 | 530 | 4,8 | 830 | 1155-1638 | 3855-5292 | 5460-7350 | |

| 2600 | 960 x 430 | 1¼" | 830 | 3350 | 3180 | 1650 | 1880 | 500 | 5 | 920 | 1430-2028 | 4810-6552 | 6760-9100 | |

| 3200 | 960 x 430 | 1½" | 1000 | 3820 | 3650 | 1650 | 1950 | 580 | 6 | 1070 | 1760-2496 | 5920-8064 | 8320-1120 | |

| 4400 | 960 x 430 | 1½" | 1150 | 4070 | 3900 | 1850 | 2140 | 610 | 7 | 1510 | 2420-3432 | 8140-11088 | 11440-15400 | |

| 5200 | 960 x 430 | 1½" | 1160 | 4570 | 4400 | 1850 | 2200 | 650 | 7 | 2130 | 4200 | 14500 | 19800 | |

| 6000 | 960 x 430 | 1½" | 1160 | 5070 | 4900 | 1850 | 2220 | 650 | 7 | 2530 | 3300-4680 | 11100-15120 | 15600-2100 |