VP Standard Pneumatic Presses

The SRAML VP Standard line of pneumatic membrane presses represents our commitment to high-end professional winemaking, with a number of upgrades and possible customizations tailored to your production style to result in superior performance and premium wines.

Equipped with a large user-friendly touchscreen terminal for a wide range of personalized pressing options, axial loading, a highly efficient Becker compressor and additional side panels for easy cleaning and maintenance, the SRAML VP pneumatic presses meet the needs of even the most demanding wineries.

With increased input capacity, reduced pressing time and a most gentle pressing operation, VP press makes sure you achieve maximum yields and quality with minimal effort.

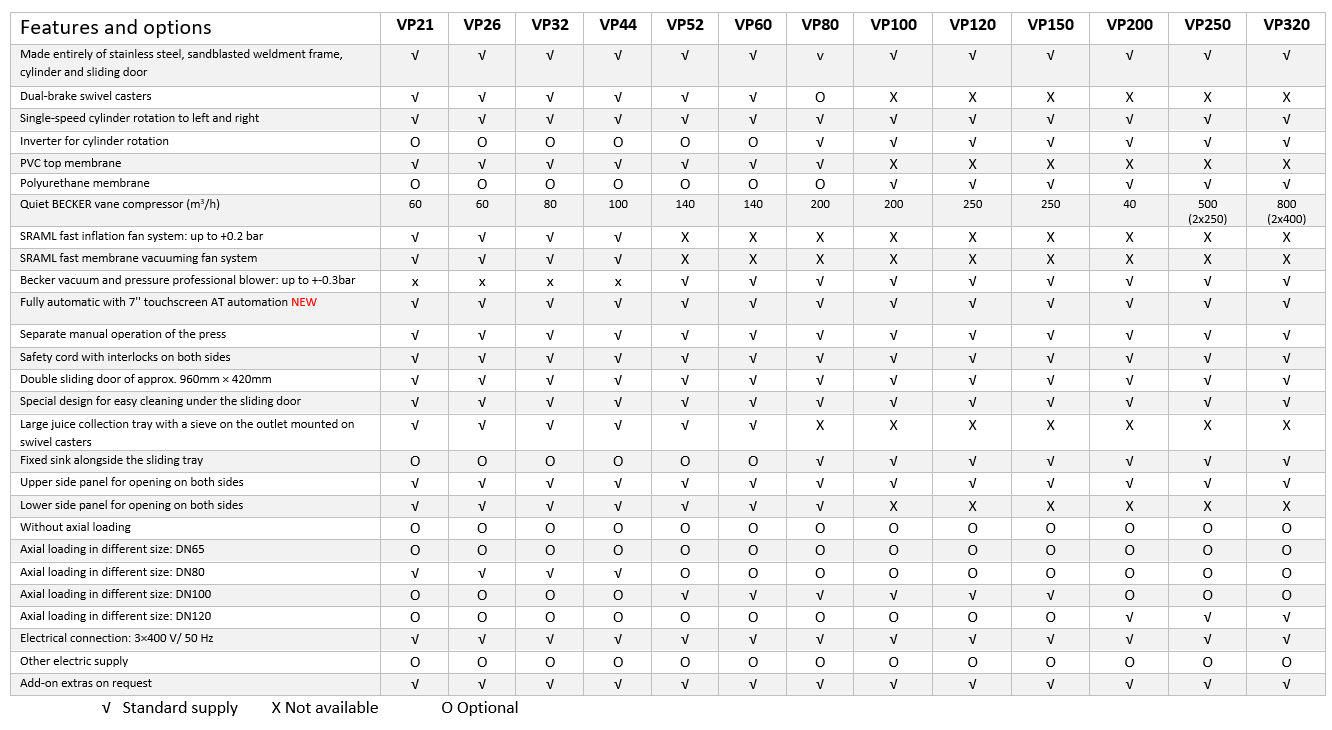

VP Standard Pneumatic Press features include:

- Large touchscreen terminal with a number of pressing cycles, personalized options and a graphical display of the pressing progress

- Central loading valve

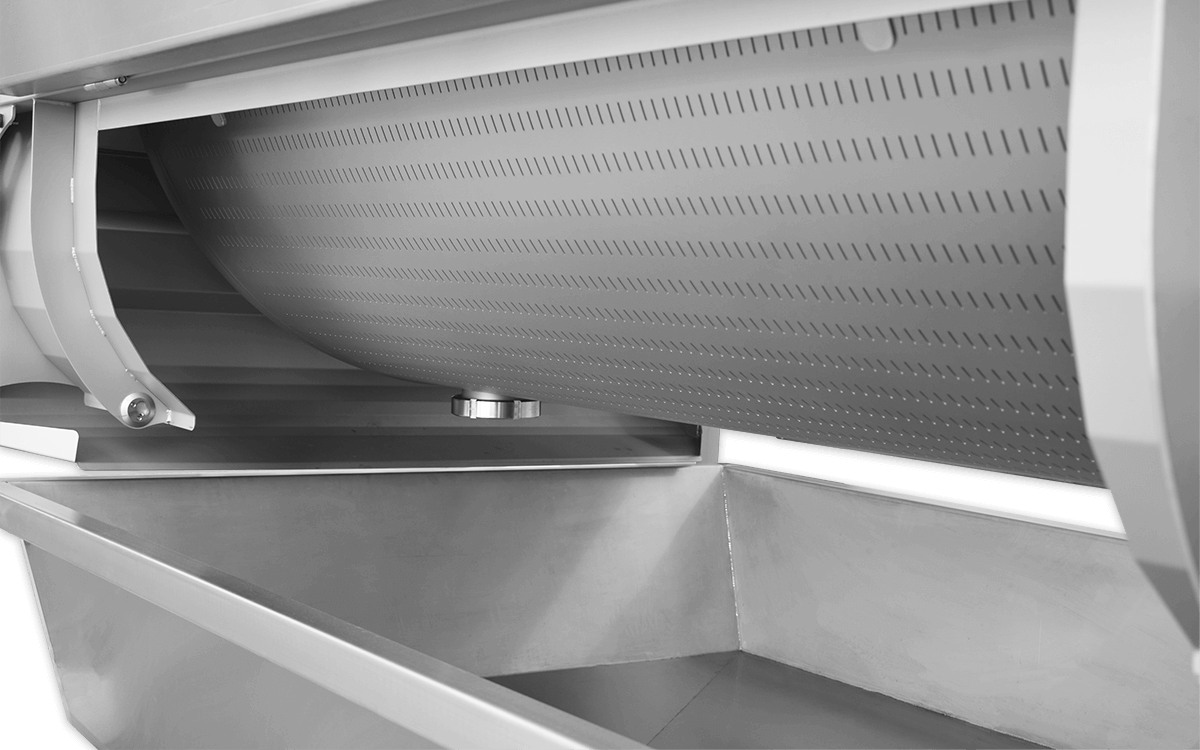

- Electropolished drain channels

- Ultra-quiet and highly efficient Becker compressor for high-pressure pressing

- Built-in fan for rapid inflation at low pressure

- Mobile juice collection tray with sieve on the outlet

- Extra-large dual sliding door to provide easy interior access for loading, unloading and cleaning

- Hinged side panels to provide complete access to the rotating drum during cleaning and unloading

- Open or closed-cage pressing system

- Hygienic design

Product specifications

- Made entirely of stainless steel

- Dual-brake swivel casters with models VP26, VP32, VP44, VP52 and VP60

- Cylinder rotation to both sides: left–right

- Mirror-polished drainage channels

- Quiet BECKER vane compressor

- Quiet fan for fast airflow: up to +0,2 bar

- Quiet fan to vacuum the membrane

- Axial loading

- AT automation with touch screen terminal

- Separate manual operation of the press

- Safety cord with interlocks on both sides and at the back of the press

- Large door opening on the cylinder

- Large double sliding door

- Special design for easy cleaning under the sliding door

- Large mobile juice collection tray with a sieve on the outlet

- Central opening of the upper sides

- Central opening of the lower sides

- Declaration of Conformity (CE marking)

- PED documentation

Automation control

- Automatic AT10 (10” touchscreen)

- Collection tank level switch

- Soft start-stop with smart cylinder rotation speed control

- Cord or radio remote control

- Inert gas system without inert gas recovery

- Weighing system

- Separate electric box for AT 7” or AT 10” display

- Acoustic alarm on central loading and automatic stop on external pump with axial loading

- Other electrical supply

Axial loading

- Pneumatic (pinch) valve

- Elbow sight glass to monitor mass flow in front of the valve for axial loading

- Inert gas injection system for maceration in inert atmosphere

Cylinder

- Non-perforated door for maceration

- Plugs to seal drain channel outlets

- Installation/orientation of the press to the right

- Drain channels on the hinges

- Pneumatic watertight sliding doors with inflatable seal

- Pneumatic drive to open and close the double doors

- Central juice outlet (installed INSIDE the drum)

- Central juice outlet (installed OUTSIDE the cylinder)

- Double jacket on the cylinder for cooling/heating purposes

- Apple pressing net

- Electro-polished sliding doors

- Manual butterfly valves on drain channels

- Polyurethane membrane

Frame

- Elevated press

- Staircase platform by the press

- Additional stairs on the other side of the platform

- Different side panel opening and closing options

- Motorized movement of the press

- Drawbar for moving the press

- Fixed sink with the sliding tray

- Large presses mounted on wheels to be moved easily around the winery

- Press without side panels

Cleaning

- Cylinder external washing

- Manual interior cleaning of drain juice channels and a sewer with high-pressure washer

- Automatic interior cleaning of drain juice channels and a sewer with high-pressure washer

- Automatic PULSE (water–air) drain channel cleaning

Loading hoppers

- Loading hopper

- Loading hopper with crusher

- Loading hopper mounted on a stand-alone trolley

- Loading hopper with crusher mounted on a stand-alone trolley

| Name |

|---|

| VP21 |

| VP26 |

| VP32 |

| VP44 |

| VP52 |

| VP60 |

| VP80 |

| VP100 |

| Cylinder volume Vc (L) | Length x Width (door) L x W (mm) | Sink diameter Ds (Ø) | Sink volume Vs (L) | Length with axial loading Lcp (mm) | Length L (mm) | Width W (mm) | Height H (mm) | Marc discharge height Hc (mm) | Power supply with integrated compressor (kW) | Dry weight (kg) | Whole grapes – loading through door (kg) | Fresh destemmed grapes – axial loading (kg) | Fermented grapes – axial loading (kg) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2600 | 760x430 | 1¼ | 800 | 2.280 | 2.700 | 1.600 | 1.990 | 610 | 6 | 1020 | 1155–1638 | 3885–5292 | 5460–7350 | |

| 2.600 | 960 x 430 | 1¼" | 1.015 | 3.380 | 3.200 | 1.600 | 1.990 | 610 | 6 | 1.150 | 1.430-2.000 | 4.800-6.550 | 6.750-9.100 | |

| 3.200 | 960 x 430 | 1½" | 1.400 | 3.880 | 3.700 | 1.650 | 1.990 | 610 | 7 | 1.310 | 1.760-2.500 | 5.920-8.000 | 8.320-11.200 | |

| 4.400 | 960 x 430 | 1½" | 1.600 | 4.070 | 3.900 | 1.850 | 2.220 | 650 | 8,5 | 1.630 | 2.400-3.430 | 8.140-11.000 | 11.440-18.200 | |

| 5.200 | 960 x 430 | 1½" | 1.860 | 4.570 | 4.400 | 1.850 | 2.220 | 650 | 12,2 | 2.130 | 2.860-4.056 | 9.620-13.100 | 13.520-18.200 | |

| 6.000 | 960 x 430 | 1½" | 2.100 | 5.070 | 4.900 | 1.850 | 2.220 | 650 | 12,2 | 2.530 | 3.300-4.680 | 11.100-15.120 | 15.600-21.000 | |

| 8.000 | 730x440 (Sliding doors with pneumatic drive and inflatable seal) | 1½" | 1.000 (available only version with sliding tray) | 5.300 | 5.100 | 2.360 | 2.850 | 850 | 23 | 3.700 | 4.440-6.240 | 14.800-20.160 | 20.800-28.000 | |

| 10.000 | 730x440 (Sliding doors with pneumatic drive and inflatable seal) | 2" | 1.150 (available only version with sliding tray) | 6.300 | 6.100 | 2.360 | 2.850 | 850 | 23 | 3.950 | 5.500-7.800 | 18.500-25.200 | 26.000-35.000 |