DS-type destemmer

Designed to process small or large quantities of grapes unloaded from belt elevator or grape trailers, the DS-type destemmer, equipped with a hopper auger for a uniform grape supply, ensures a most gentle and efficient separation of grape berries from the stems.

Available with inline sliding crusher, the SRAML DS-type destemmer series features a loading hopper and mechanically controlled auger to feed the grapes into the PVC cage to be stemmed, length- and inclination-adjustable rubber tips on the destemming shaft and electronic speed variator to control the cage and shaft rotation.

Its heavy-duty stainless-steel frame is mounted on telescopic legs with caster wheels to be easily adjusted to any environment and operating condition.

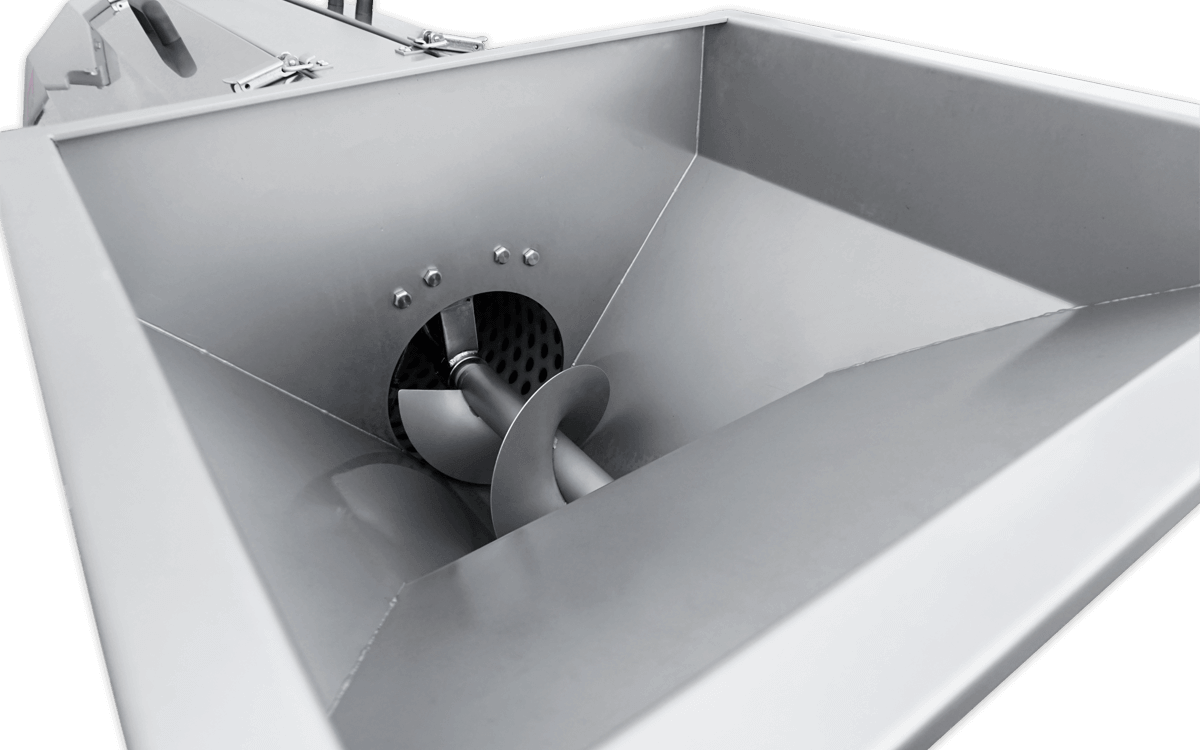

- Large loading hopper with independent auger drive for easy adjustment of the incoming grape load

- Polyethylene cage available in different hole sizes

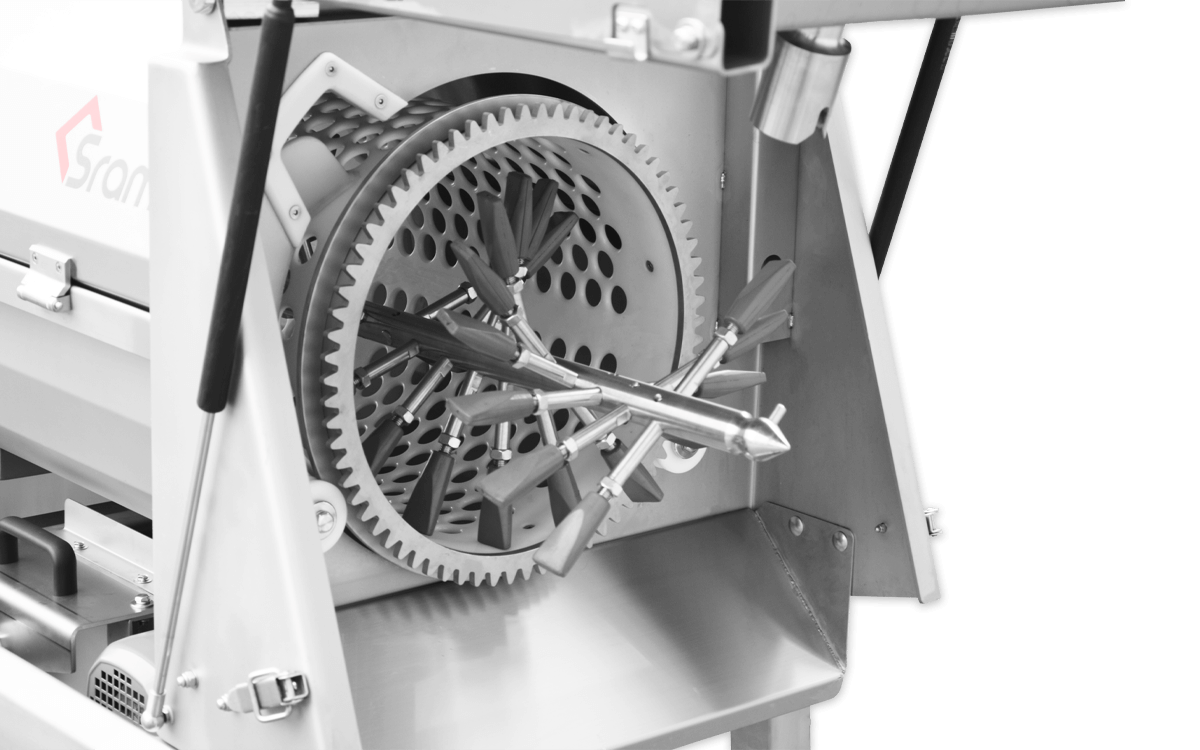

- Destemmer shaft with soft rubber tips adjustable by length and inclination

- Electronic speed variator to control the cage and shaft rotation

- Simple to operate

- Easy and fast tool-free (dis)assembly

- Easy access to the interior for efficient cleaning and maintenance

Product specifications

- Large loading hopper with independent auger drive and mechanical speed variator enabling easy adjustment of the incoming grape load.

- Polyethylene cage holes of 22 mm as standard (mixed 25/22 mm holes as standard with the D25 version). Optionally available also in stainless steel and/or in different sizes.

- Simple variable speed control of the shaft and cage by means of inverter. Cage rotation speed is linearly dependent on the speed of the rotor.

- Destemmer shaft with soft rubber tips adjustable by length and inclination.

- Destemmer cage and shaft rotate in same direction.

- Made entirely of AISI 304 stainless steel. Telescopic legs on caster wheels allow for easy output-height adjustment.

- Control panel with buttons to start–stop the operation, potentiometer for shaft and cage speed regulation, and emergency stop button.

- Side opening panel allows simple removal of the cage and shaft for easy cleaning.

- Wide back panel opening enables easy access and cleaning of the machine’s interior.

OPTION: Inline crusher with independent drive allows the machine to operate in 3 different modes:

- Destemmer and crusher simultaneously

- Destemmer only — an easy slide of the crusher to the back of the machine

- Crusher only — when removing the cage and shaft from the destemmer

- Inline sliding crusher

- Mass collection tank with screw

- Different machine electrical supply

- Drainage grates at the bottom of the hopper

- Frame on swivel casters without telescopic legs

Mechanical harvest adjustment: Hopper with draining sieve

A sieve at the bottom of the intake hopper plays a major role in the reception of mechanically picked grapes. The juice released from grape berries upon reception gets drained at the entrance and is prevented from getting into the cage. Overflow is restrained and the destemmer can run on minimal speed. The juice is not exposed to physical effects of the moving parts and oxygenation as it is collected and fed directly into the pump. The draining sieve is designed to maintain hygiene while being simple to clean

Polyethylene cages

Models DS7, DS10 and DS15

- Polyethylene cage with holes of ⌀ 18 mm

- Polyethylene cage with holes of ⌀ 22 mm

- Polyethylene cage with holes of ⌀ 30 mm

- Polyethylene cage with mixed holes of ⌀ 22/16 mm

Model DS25

- Polyethylene cage with holes of ⌀ 18 mm

- Polyethylene cage with holes of ⌀ 22 mm

- Polyethylene cage with mixed holes of ⌀ 22/18 mm

- Polyethylene cage with mixed holes of ⌀ 25/22 mm

- Polyethylene cage with mixed holes of ⌀ 30/22 mm

| Name |

|---|

| Destemmer DS7 |

| Destemmer DS10 |

| Destemmer DS15 |

| Destemmer DS25 |

| Destemmer DS50 |