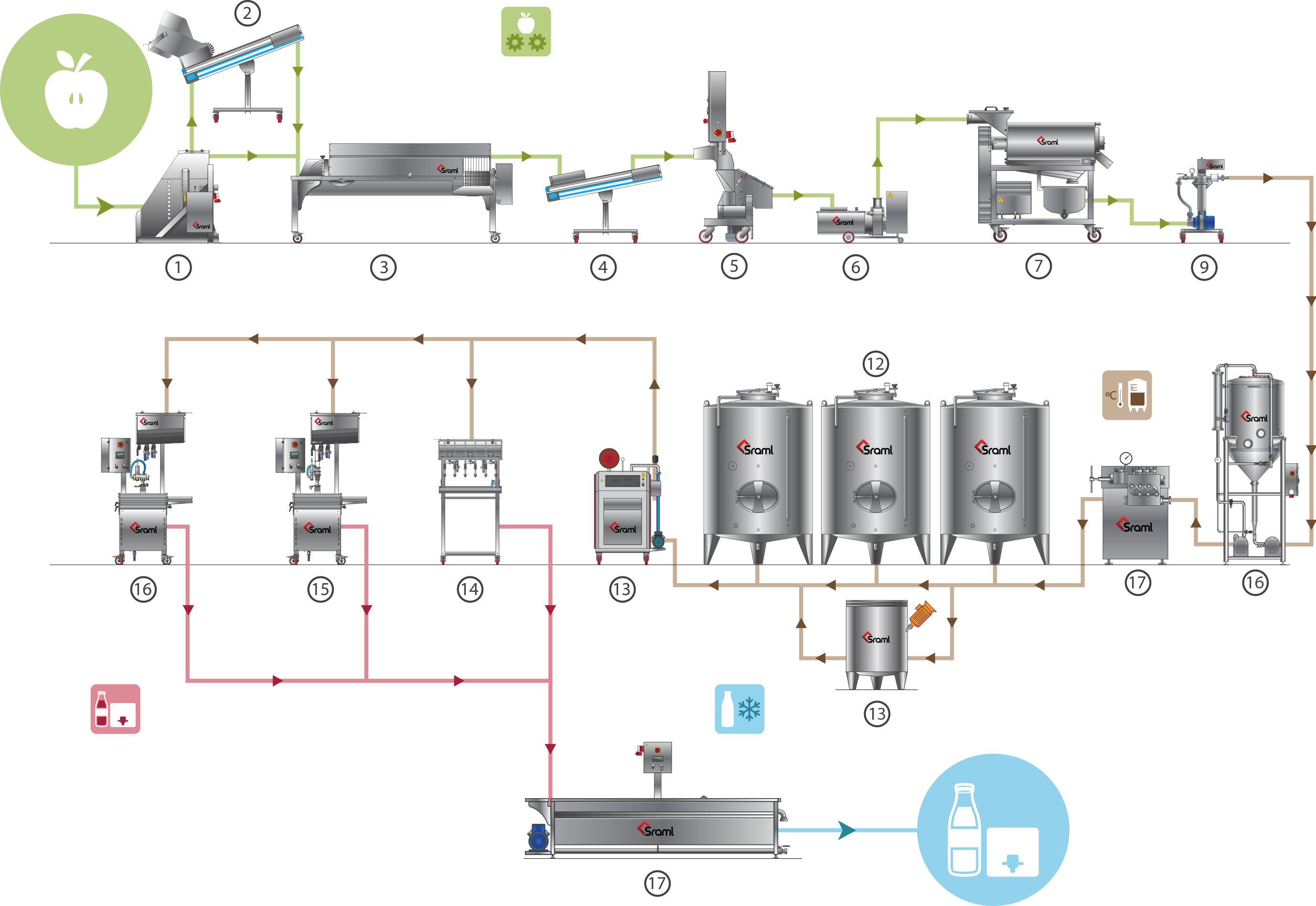

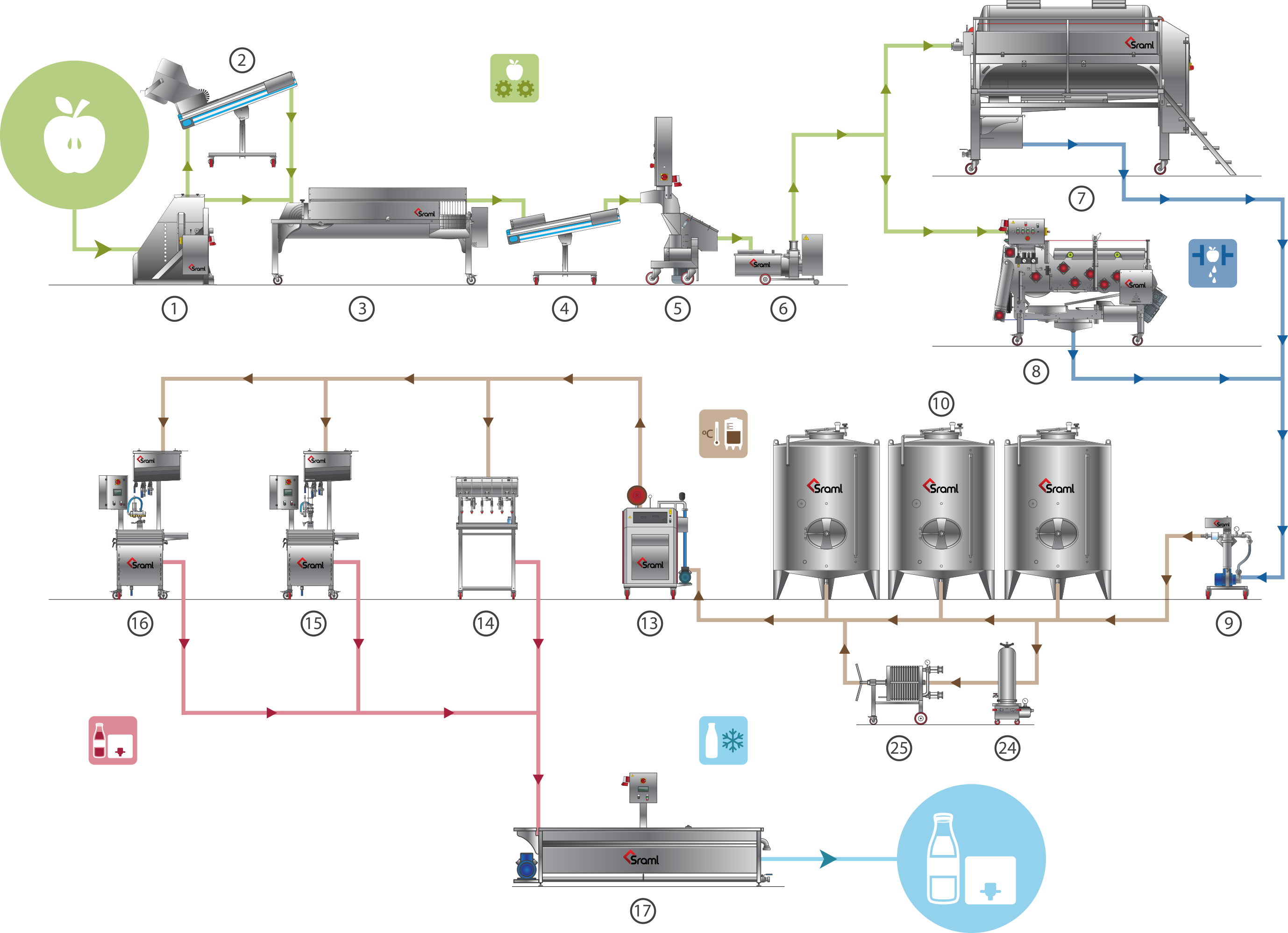

Pome fruit purée processing technology

Natural and concentrated pome fruit purées are used in a variety of finished food products such as smoothies, mixed juices, nectars, baby food, jams, fruit preparations and fillings for pastry, yogurt and ice cream.

Purées differ significantly from juices because all the processing steps involve pulp that is highly viscous, which represents an end-to-end challenge for the equipment used. SRAML fully comprehensive fruit processing equipment, ranging from sorting conveyors to pulpers and filling lines, is just what you need to process pome fruits into high-quality purées, whether you are handling apples, pears, nashi or quince.

To prepare pome fruit for pulping, a grating mill may be used to grind it into fine mash which is passed through a pulper finisher and reduced to a liquid purée free of seeds, skin and fibres.

To maximize the pulping efficiency, pulping is applied in double stages. At this point, the purée may have air mixed in it and needs to pass through a deaerator to retain the colour and flavour of the fresh fruit. The purée can undergo homogenization to increase viscosity.

SRAML fruit processing solutions ensure that the pome fruit purée is treated as gently as possible to get the most – and the best – out of the fruit.