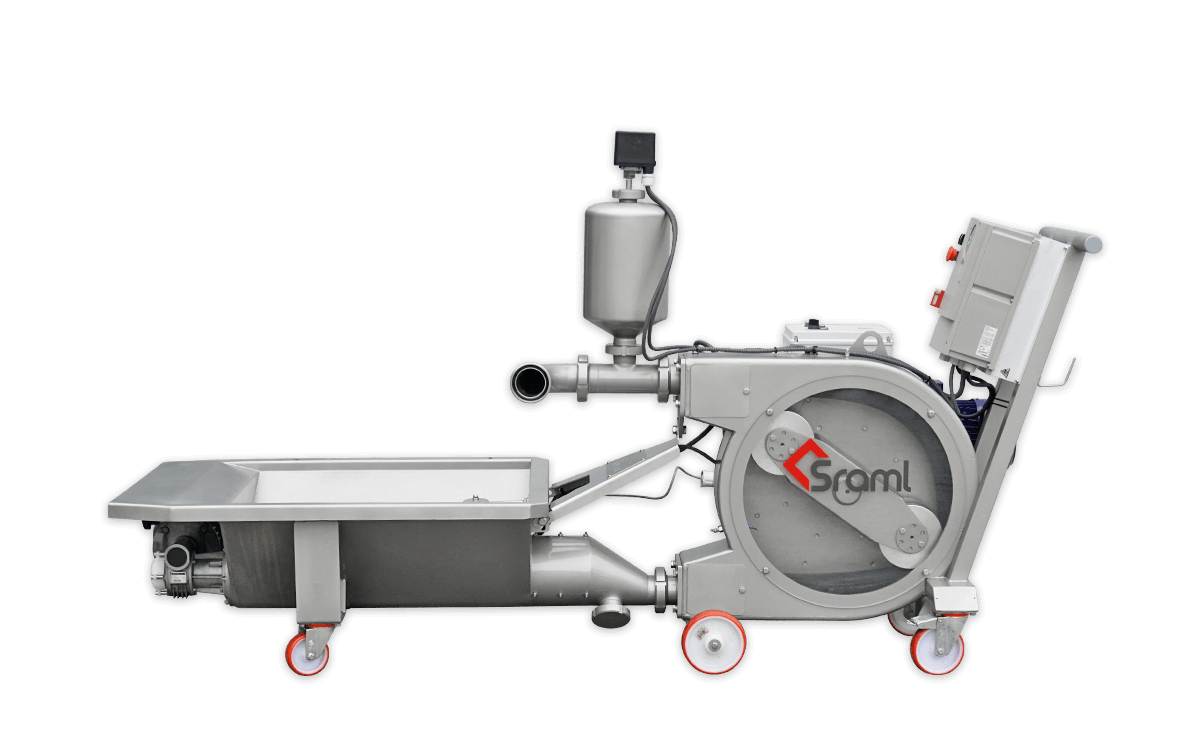

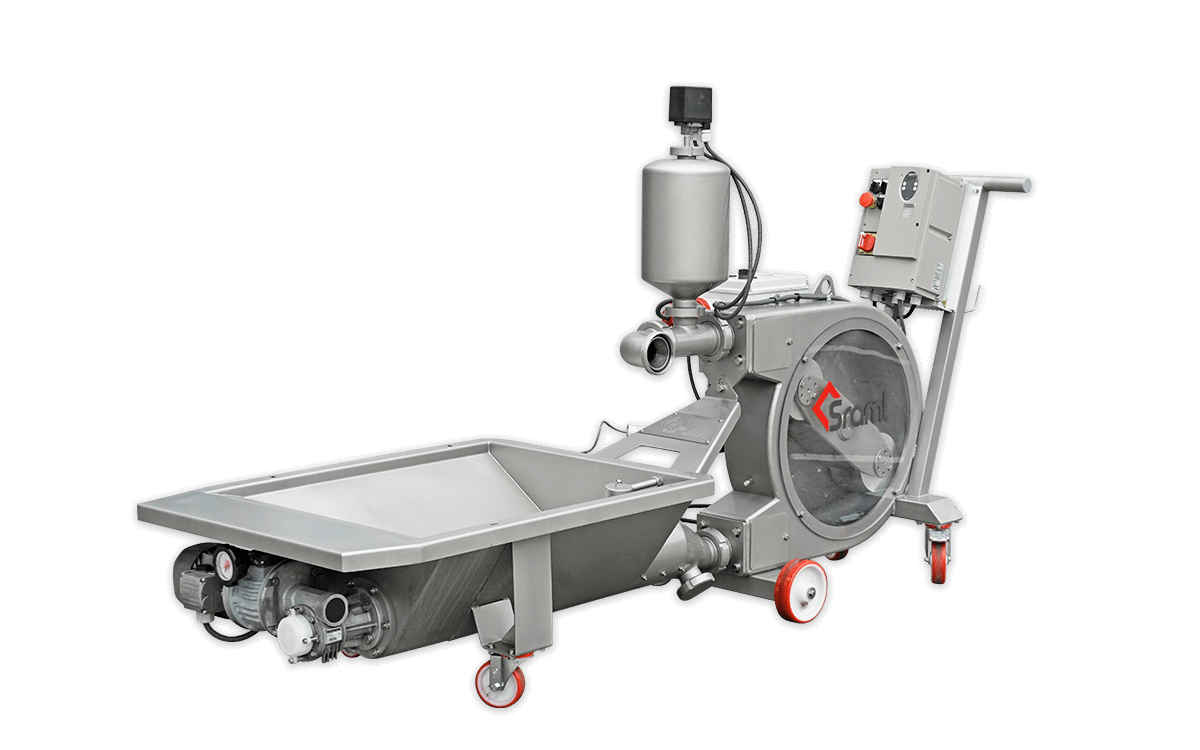

MPP peristaltic pump

Equipped with a hopper and a feeding screw to enable equal dosing of a medium to the pump, the SRAML MPP peristaltic pumps serve as the perfect tool for collecting berries, mash or fermenting mass, gently moving the product from one processing phase to another.

The SRAML MPP Peristaltic Pump supports a smooth, continuous transfer without any contact between the product and mechanical drive components, keeping the medium intact. An inverter is fitted to the motor to enable exact adjustment of the flow rate and precise dosage.

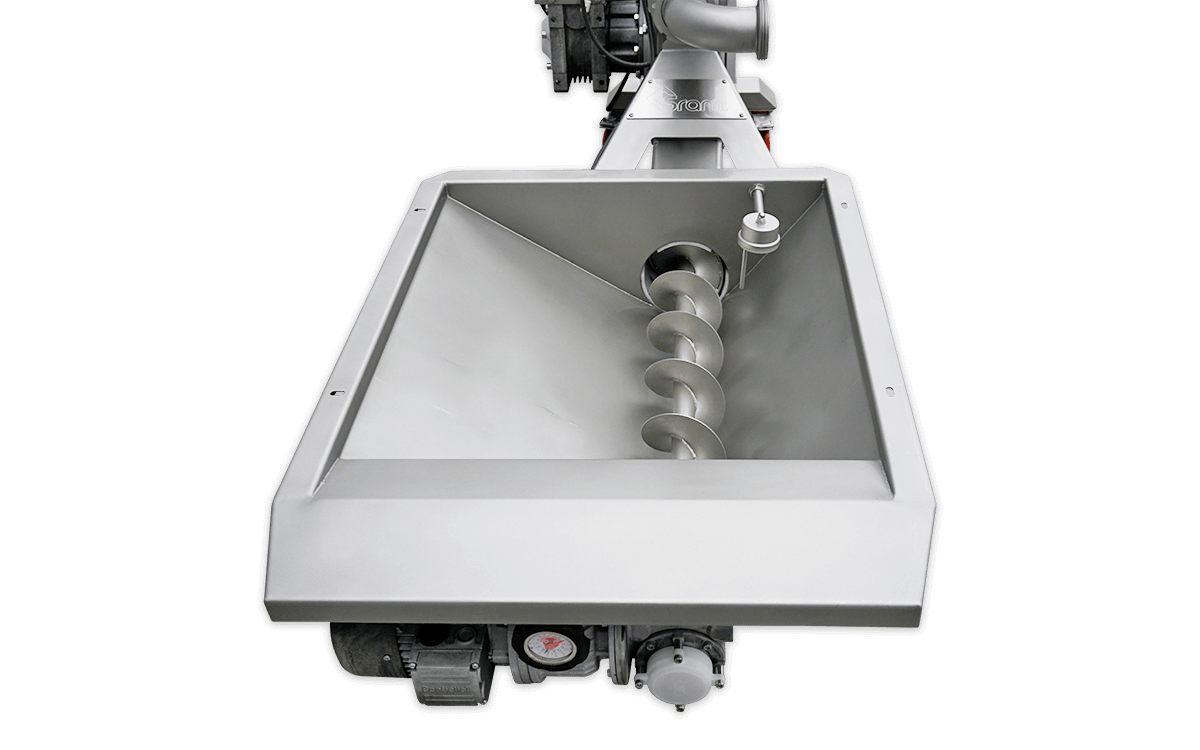

The auger of the feeding hopper collects and supplies the MPP Peristaltic Pump with grape mass at an even rate, moving up to 18 500 kg of grape load per hour. The hopper can be easily detached from the pump when not needed, e.g. for the purpose of pumping liquids.

Available in different models and add-on extras, the MPP pump series is self-priming to be run dry without any damage to the pump, reversible to be run in both directions, simple to use, easy to clean and very gentle on the medium being pumped.

- Highly efficient transfer of berries, mash, fermenting mass as well as liquids

- Hopper with feeding auger for equal dosing — easily detachable when pumping liquids

- Easily variable between low and high flow rates for maximum efficiency

- Pumping capacity of up to 18,500 kg per hour

- High self-priming capacity

Product specifications

- Suitable for a wide range of contents, e.g. fresh destemmed grape, whole grape, mass, juice and wine

- AISI304 stainless steel structure with EPDM tubing for total hygiene

- Perfectly smooth inside surface for excellent performance

- The rotating rotor repeatedly squeezes the tube between 2 rollers (3 rollers on request) and the pump housing

- The pumping process is soft and delicate — the pumped medium and mechanical parts do not come into contact

- The hopper, attached to the pump body by means of a DN clamp unit, comes with feeding screw and independent motor drive to provide equal dosing of the medium to the pump.

- The feed hopper is very easy to remove. Once removed, the pump could be used for pumping liquids.

- Supplied with two compensation chambers to ensure a constant flow and a pressure switch at the outlet to protect the pump from overloading

- Reversible flow: the product can run in both directions

- Self-priming up to 7 m under pump level

- Electrical box with frequency regulator for speed control

- Mounted on a trolley with two fixed wheels and two dual-brake swivel casters to be easily moved around the winery

- Hygienic, simple design and compact dimensions for easy dismantling and cleaning

- Remote control

- Different electrical supply

Models with hopper MPP

- Level probes (min–max)

- Screw reverse rotation

- Screw for hopper with inverter

| Name |

|---|

| MPP 1-10 |

| MPP 3-20 |