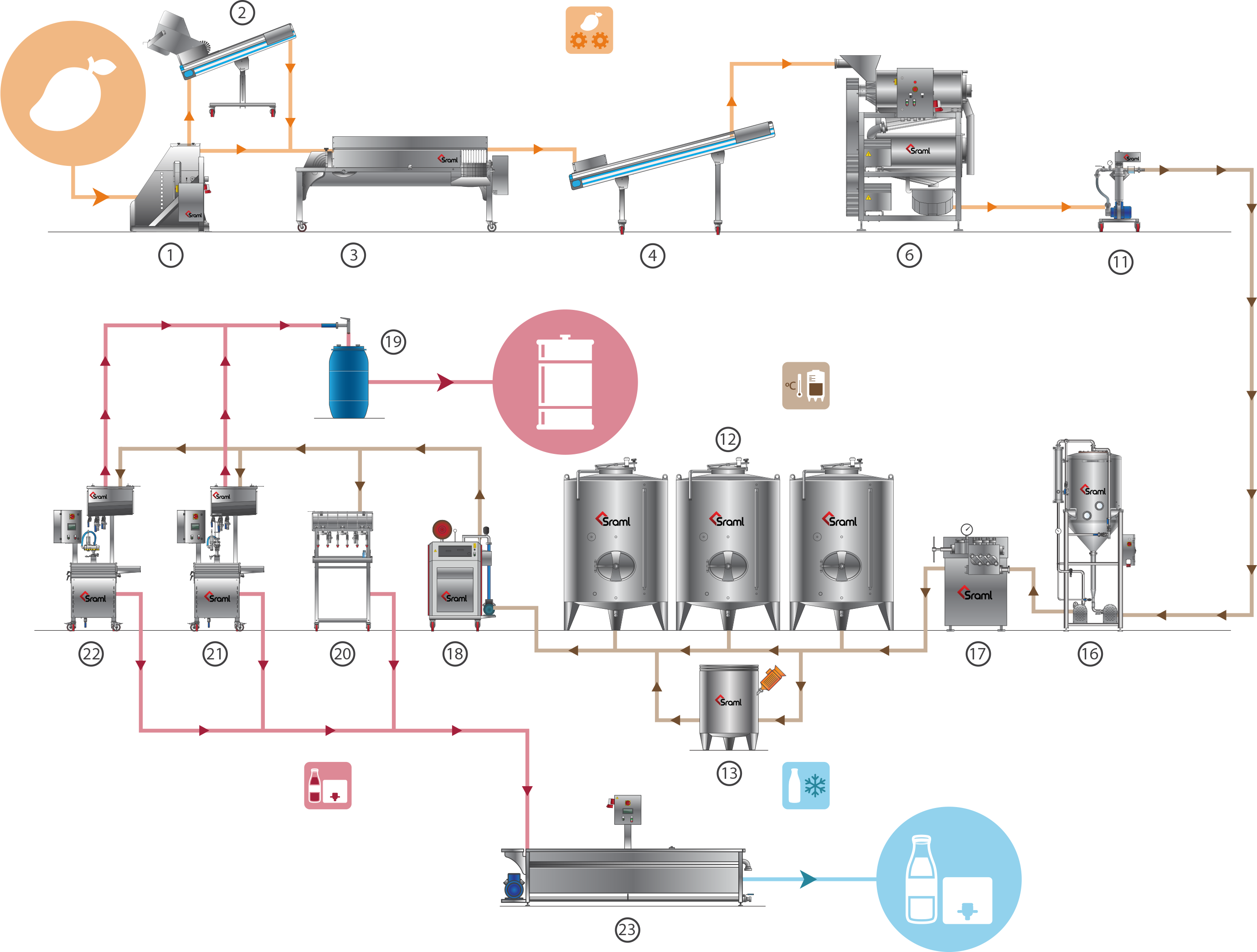

Mango purée processing technology

Natural and concentrated mango purée is used in a variety of finished products such as juices, smoothies, mixed juices, nectars, baby food, jams, fruit preparations and fillings for pastry, yogurt and ice cream.

Purées differ significantly from juices because all the processing steps involve pulp that is highly viscous, which represents an end-to-end challenge for the equipment used. SRAML fully comprehensive fruit processing equipment, ranging from sorting conveyors to destoner‒pulper units and filling lines, is indispensable in the processing of mangoes into high-quality smooth viscous purée.

Fully mature, even soft, but not overripe mangoes are typically not extracted as pressed juice but rather as purée. Once sorted and washed, the mangoes are passed through the destoner‒pulper to have the stone, skin and fibre removed, and the destoned mash reduced to a consistent purée. The presence of bitter substances in the peel requires a complete removal of the peel from the purée, which is achieved by a special rotor and screen of the SRAML destoner.

Mangoes can be heated prior to pulping, making the pulping process easier, oxidation reduced and cloudiness stabilized. To maximize the pulping efficiency, pulping is applied in double stages. At this point, the purée may contain air and needs to be passed through a deaerator to preserve its colour and flavour. The mango purée can undergo homogenization to increase viscosity.

SRAML mango processing solutions ensure that the purée is treated as gently as possible to get the most – and the best – out of the fruit.