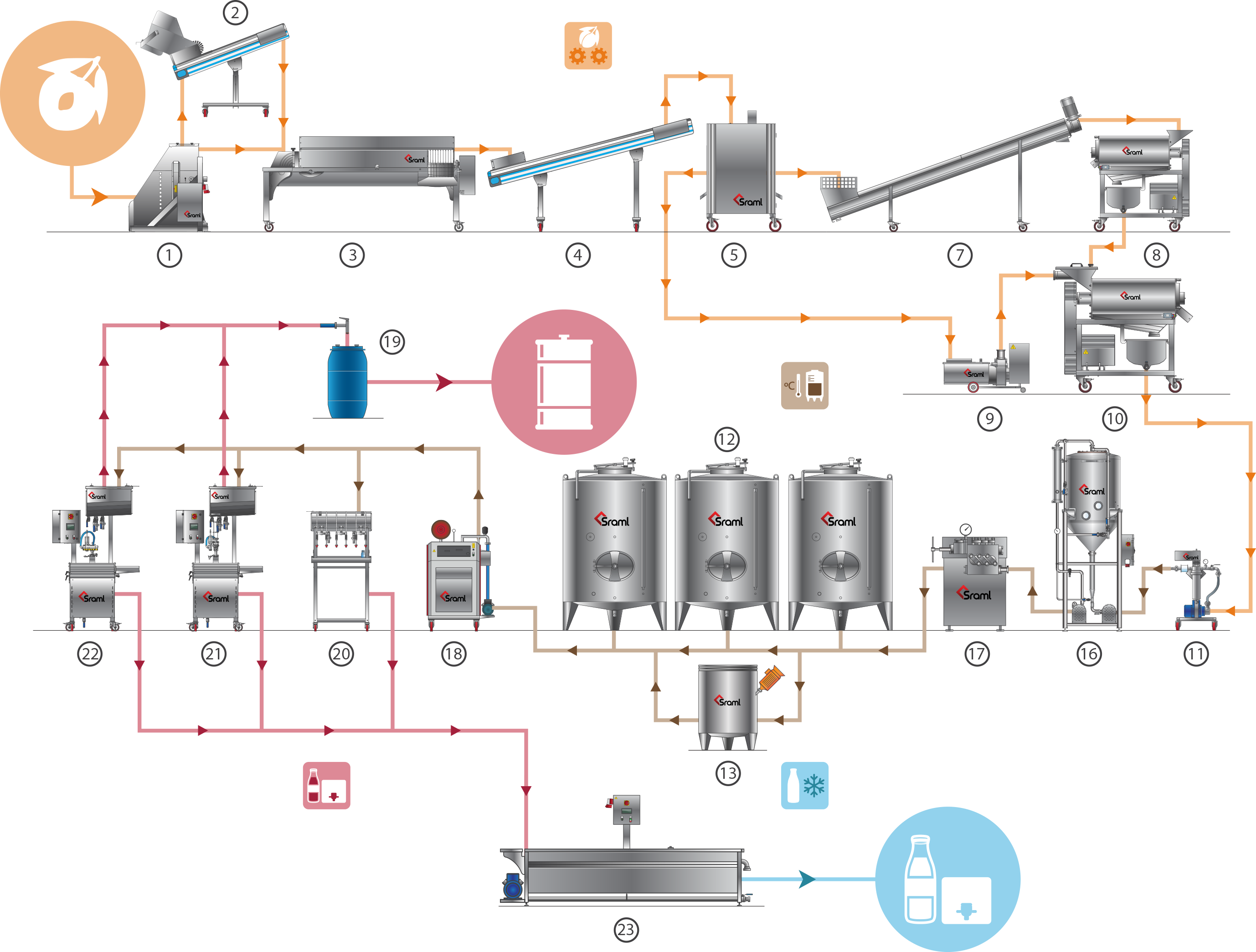

Peach purée processing technology

Natural peach purée is used in a variety of finished products such as smoothies, mixed juices, nectars, baby food, jams, fruit preparations and fillings for pastry, yogurt and ice-cream.

Typically, fully ripe peaches are not extracted as pressed juice but rather as a purée prepared from washed and selected fruit, which is destoned and passed through the pulper machine to be reduced to a liquid. Peaches can be heated prior to pulping, making the pulping process easier, oxidation reduced and cloudiness stabilized.

For maximum efficiency, pulping is applied in double stages. At this point, the purée may have air mixed in it, which can lead to deterioration of its colour and flavour, and needs to be passed through a deaerator to preserve the characteristics of the fresh fruit.

With SRAML filling and packaging technology, the purée can be stored in bags within drums as a semi-finished product or prepared as peach nectar.

SRAML fruit processing solutions ensure that the peach purée is treated as gently as possible to get the most – and the best – out of the fruit.