Extracting only the best from grapes

At first glance grape pressing could be considered an extremely simple operation in the winemaking process. But is that really true? The main aim of pressing is to separate the juice from the solids found in bunches of grapes. If we consider it closely, it immediately becomes clear that an appropriate pressing process makes it possible to avoid many undesirable outcomes that can have negative effects on the quality of the juice, and thus greatly influence the quality of the wine made from it.

The following steps outline the facts that contribute to a better understanding of the pressing of grape mass, and the key factors such as those impacting the quality of the resulting wine. For the sake of convenience, the pressing process is defined as an extraction of juice and other substances from solid particles of a grape berry (its skin, seeds, flesh).

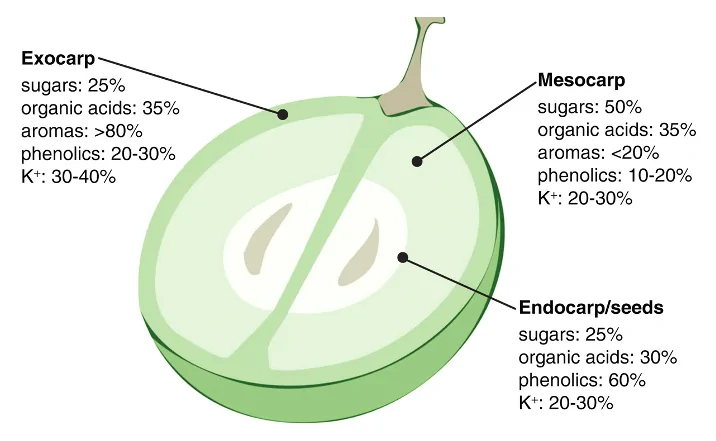

As this distribution varies significantly in the various parts of the grape berry, it is necessary to adapt the winemaking method accordingly. In order to obtain the best quality must, we need to take full advantage of the juice extracted from the grape berry mesocarp, which is rich in sugars and organic acids, and contains naturally occurring aroma compounds. When extracting juice from the exocarp, we must be careful as it contains more potassium and phenolic compounds. It may also contain high amounts of aromatic compounds that have a significant impact on the quality of the wine made from it. Pressing must be carried out very carefully, and a shorter maceration period may be of great help here. When making quality wines, it is better to avoid juice from the central part of grape berries, as it contains high amounts of phenolic compounds that give wine a bitter and tannic taste.

Grape reception, destemming, sorting and pressing must be carried out in a relatively short period of time in order to prevent a decline in quality and oxidation. The goal is to obtain juice that is as clear as possible and that suits the preferred quality parameters. With the procedures carried out prior to fermentation it is important to:

- enable extraction and dissolution of aromatic compounds and their precursors from the skin (exocarp),

- limit the leaching of plant (unripe) aroma compounds and substances from the parts of grapes (stems, seeds, skins) causing an astringent taste,

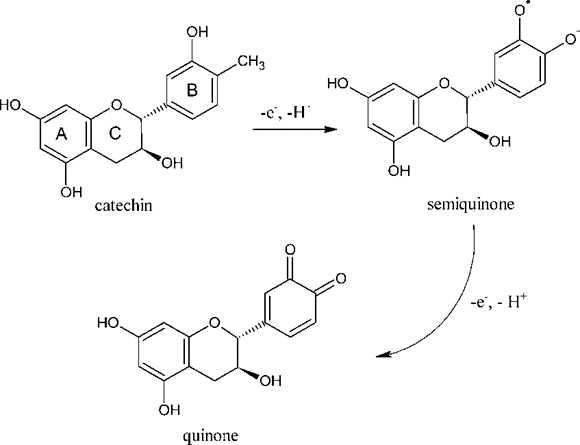

- prevent the occurrence of substances influencing the stability of aromatic compounds. Oxidised or oxidising phenolic compounds may bind sensitive aromatic molecules.

What are ‘quinones’? Quinones are a product of the oxidation of phenolic compounds from grape juice, and react with volatile thiols during the alcohol fermentation. Such wines have no characteristic varietal and fermentation aroma compounds. When making wine, oxidised must should be avoided or processed separately. During the processing and pressing further oxidation and additional extraction of phenolic compounds must be limited as much as possible. Mechanism of catechin oxidation to quinone (Oliveira-Brett & Kozminski, 2006). |

The grape mass may enter a grape press in various states: in the form of whole berries, a macerated mass or fermented mass. Loading methods also vary: directly through a door, receiving hoppers, from fermenters, central loading and so on.

Pressing of whole grapes is carried especially in cases when extraction from the exocarp is not preferred. The juice obtained in this way has less colour and contains less phenolic compounds. The resulting wines are softer and more refined, with less coarse tastes (bitter, tannic, astringent) and without any ‘unripe’ taste. Pressing whole grapes reduces the possibility of juice oxidation.

Whole grapes may be loaded directly by transferring them from containers or emptying transport trailers through the grape-press door, through a feeding hopper or by means of a conveyor belt.

Stems contribute a lot to draining, as they act as capillary drain channels in a hard cake. If the stems are removed then the pressure must be applied for longer, and more loosening cycles are needed in the pressing programme. Pressing whole grapes also contributes to protein stability in white wines, reducing the need for bentonite during the next stages compared to wines made by pressing destemmed mash.

Loading the grape press must be adapted to the organisational, logistic and technological demands and capabilities of a wine cellar, which is also the reason why investment in a grape-press is not carried out by simply examining what’s in stock, but rather represents an individual technological solution. In light of this, Sraml grape presses offer various loading possibilities regardless of the size and automation level, and may be completely tailored to the demands of each winemaker and the preferred pressing technology.

The central loading of a grape press is carried out by loading mash into a press cylinder through a central valve. The advantage of such an approach is that it enables draining during loading, allowing the cylinder to be filled up to twice the size of its volume. Moreover, this type of pressing is carried out faster compared to pressing whole grapes.

We should also mention that pressing mash results in a cloudier juice with a higher content of colloid particles. These are released into the discharging juice before the cake, which acts as a particle filter, is formed. As regards the central loading procedure, we recommend that the drain channels are kept closed at the beginning of the loading process. Start draining when the grape-press cylinder is at least half full.

When choosing a new grape press, Sraml’s experts recommend upgrading the basic press model with a central discharge outlet to enable the juice to be collected directly in a hopper or tank. Since a long hopper under the grape press cylinder is not needed, a smaller hopper can be used. A smaller hopper is very helpful in reducing the exposure of juice to air and thus the negative effects of oxygen, as well as must oxidation.

In order to extract only the best from grapes, attention must be paid to the preparation of mash, the grape-press loading method, draining, grape mass (‘cake’) loosening and cake thickness. Attention must be paid to the influence of shear forces on the cake, pressing time and yield. When talking about ‘soft’ pressing, all these factors should be taken into account and their impacts on the quality of the must should be recognised.

Before starting the pressing procedure, the following basic advice should be taken into account:

- High pressure does not improve the pressing effect, as it leads to the narrowing of drain and capillary channels.

- Alternating pressing, cake loosening and increasing pressure during pressing have an additional physical effect, resulting in cake kneading and shredding. The extraction of undesirable phenolic compounds is increased – wines made are very coarse, tannic, bitter and astringent.

- Pressing a thinner cake requires less time, but the juice obtained contains much more colloid (solid) particles, as the filtration effect is much smaller due to a shorter path through the organic mass.

When extracting juice from grape berries it is advisable to pay attention to the content of colloids in the juice that is obtained. Sedimentation is slow and mostly ineffective. Furthermore, fermentation of cloudy must has a negative impact on the quality of the future wine. The extraction procedure has to be carried out in such a way that the concentration of colloid particles in the resulting juice will be as small as possible, which will contribute greatly to the successful clearing of juice prior to its fermentation. Cloudy juice is the result of unrefined processing, and such wines have a more distinct and unripe character. If the pressing method produces very cloudy juice, issues may arise during the clearing procedure that may latter be reflected in the quality of wine.

When pressing attention should be paid to limit the effects of oxygen effect (and thus the possibility of oxidation), extraction of phenolic compounds from the skins, seeds and stems, and to prevent any increase in the pH value of juice, which may rise as a result of potassium extraction from the solid particles of grapes. Such impacts can be avoided by adapting the pressing procedure and observing the following guidelines:

- Keep the pressing pressure as low as possible,

- Reduce mechanical impacts such as grinding and kneading of the mass being pressed,

- Increase pressure in a slow and controlled manner,

- Extract as much juice as possible at low pressures and during the first cycles,

- Make sure the temperature during pressing does not exceed 20 °C,

- Keep the number of loosening cycles as low as possible,

- Keep contact with oxygen minimal – use inert gases and antioxidants.

Modern pneumatic presses may adapt the pressing method and program to the characteristics of the grape mass and winemaker’s technological objectives. The following must be taken into consideration when selecting the program:

- duration of the pressing programme,

- the quantity of grape mass,

- the preferred quality and selection of the extracted juice, based on the:

- sugar content,

- pH value,

- preferred pigment,

- phenolic-compound concentration,

- potassium concentration,

- total acid concentration and

- colloid concentration.

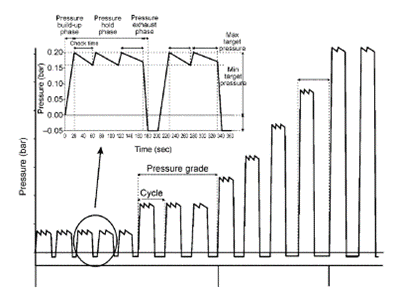

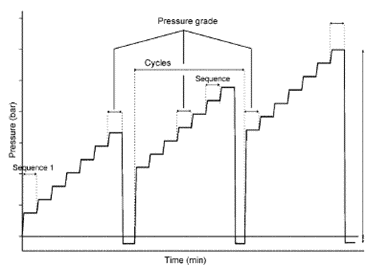

Standard pressing programs take into account the following parameters: the pressure value, cycle repetition and number of stages, draining and loosening time, number of rotations. These parameters may be applied to define pre-set programs or programs that users can simply create themselves.

Sequence programs are characterised by a progressive increase in pressure in an individual cycle. Once the draining interval is complete, the pressure increases to the next level. The pressure keeps increasing in intervals until it reaches the highest value during the cycle.

Adapting the sequence program to the characteristics of the grape mass

The pressing program should be adapted to the characteristics of the grape mass to achieve optimal results. The grape mass can be pressed lightly, moderately or heavily. The programs can also be adapted to fast or gentle pressing, or pressing with the grape press not fully loaded, taking into account the fact that the cake is thinner during the pressing process and that the draining path of juice is significantly shorter. The time the pressure is maintained can thus be shorter, and the level of loosening can be lower.

A fermented grape mass with structure cells of grape berries that have already been decomposed by enzymes can be classified into a simple pressing category. Masses of white macerated berries or grapes harvested during advanced ripeness stages can also be classified into the same category, as it is expected that structure cells of berries in such masses have already softened. Destemmed and crushed grapes can be classified into a moderate pressing category. The level of pressing increases when grapes are not ripe or with varieties that contain high amounts of pectin. In such cases the grape mass must be pressed at a higher level of mechanical impact.

The following principles apply:

– the higher the level of pressing, the slower the increase in pressure,

– the higher the level of pressing, the higher the maximum pressure,

– the higher the level of pressing, the higher the pressures in individual cycles,

– the higher the level of pressing, the higher the number of cycles,

– the higher the level of pressing, the higher the number of loosening,

– the higher the level of pressing, the longer the pressure maintained,

– the higher the level of pressing, the longer the entire pressing process.

Gentle pressing programs are adapted to prevent substances directly underneath the exocarp from leaching into the juice or to make sure that their amount in the resulting juice is low. Such a pressing method is of special significance when making sparkling wines. A slow increase in pressure, the lowest possible number of loosening cycles and finally a low final pressure all contribute to reducing the physical impact on the grape mass. In contrast, the fast pressing programs use a faster increase in pressure and a greater number of loosening cycles. In addition to faster pressing, the impact on shredding cells is stronger, and the number of colloid particles is proportionately higher.

In this context, it is worth also mentioning the grape-press loading programs that may be used for loading whole grapes through the press door or for loading the mash through the central loading valve. Cylinder oscillation or ‘swinging’ during the loading carried out through the door distributes grapes that would otherwise create a cone during loading. When loading mash through the central valve, appropriate turning of the cylinder improves draining and allows the press to be loaded with more grape mass. Turning of the cylinder prevents the pressure from increasing during loading, which otherwise occurs if the cylinder does not move and the grape mass blocks the drain channels.

After completing the pressing procedure, the emptying and cleaning stages take place. Both must be carried out quickly and thoroughly. The grape press with an elevated chassis for additional space under the cylinder is just one of the upgrades from Sraml’s wealth of innovations. To empty the elevated press, a container or trailer for dry marc can be simply placed under the door.

Unfortunately, no technological innovation or solution can overcome the fact that we are dealing with an organic mass rich in sugars and many microorganisms. Also noteworthy are fungi of various genera, acetic and lactic acid bacteria, moulds and so on, for which grapes represent a breeding ground rich in nutrients, which is why it is crucial to maintain a level of hygiene that prevents their propagation and any potential must infections that may prove fatal for the quality of wine.

Emptying the grape press must be followed by a through cylinder wash to remove the entire organic material and any juice residues. It is thus important for the winemaking equipment to enable the winemaker to carry out fast and thorough washing, to which Sraml pays great attention. Presses are made without any hidden edges and are fully accessible for washing, regardless of their size or level of automation. They are made from polished and finely sandblasted stainless steel, to which juice does not stick and which makes washing easy.

Placing a large washing opening at the lowest point of the cylinder is also of great help here, as it allows all the remaining marc and washing water to be easily washed out.

It should be noted that drain channels are often a source of impurities that provide the bacteria and fungi with a breeding ground. They represent an additional element in the cylinder that requires a lot of attention. By attaching drain channels to hinges, Sraml enables the winemaker to clean the drain channels fast, without any problems and without needing any additional help. Simply unscrew the screw to loosen the drain channel and leave it hanging on its hinges. This enables the winemaker to wash it out and reinstall it easily.

Drain channels on hinges are of great help for the winemaker when washing them.

Grape presses can be also equipped with a high pressure washer with a hose, and a special nozzle through which water sprays in all directions under pressure, making it especially useful for washing drain channels. The hose with the nozzle is simply inserted through a drain opening and the high pressure washer is started. The hose is then pushed through the drain channel with high pressure jets of water washing out the channels and removing juice residues. This option will save you a lot of time and effort, and will maintain hygiene at critical points.

We can now conclude that the pressing procedure lies at the heart of winemaking. A huge number of parameters and even more variables provide a basis for making wine of superior quality. Understanding the process, control and of course a clear idea on what kind of wine we wish to make are of paramount importance. As already mentioned at the beginning, a grape press is not a product to be bought off the shelf, but rather an individual technological solution. Pneumatic presses are without doubt Sraml’s flagship products, and machinery that allows for such a high level of adaptation to the technological process is rarely seen, so use this critical stage to your advantage to extract only the best from the grapes you have produced.

Compiled by: Marko Benčina, BSc in Viticulture and Oenology

Images: Sraml Archive, Jacqueline Macou, Missclick and Richarem

Cover Image by Jill Wellington

Sraml d.o.o., 2023, all rights reserved