SRAML STANDARD line of fillers with closed bowl is the answer to a safe and efficient bottling of liquids by applying low-vacuum or gravity while it is also easy to use and can be upgraded with a variety of add-ons. The filler bowl has a product infeed from below, minimizing product oxidation and allowing for a better emptying process. The product level in the filler bowl is controlled by a capacitive sensor. With all the settings done on a touchscreen control panel, the operator can set a precise starting and stopping point for the product inflow (minimum product level), which is set off by an alarm. The STANDARD gravity filler is equipped with electric height adjustment mechanism to allow for simple and fast changeover of bottles of similar height, even in operation.

SRAML STANDARD line of fillers with closed bowl is the answer to a safe and efficient bottling of liquids by applying low-vacuum or gravity while it is also easy to use and can be upgraded with a variety of add-ons. The filler bowl has a product infeed from below, minimizing product oxidation and allowing for a better emptying process. The product level in the filler bowl is controlled by a capacitive sensor. With all the settings done on a touchscreen control panel, the operator can set a precise starting and stopping point for the product inflow (minimum product level), which is set off by an alarm. The STANDARD gravity filler is equipped with electric height adjustment mechanism to allow for simple and fast changeover of bottles of similar height, even in operation.

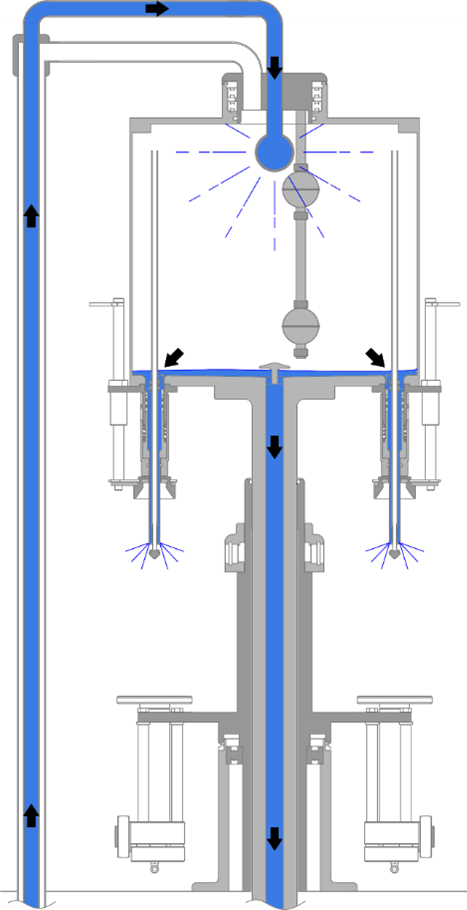

Thanks to a special stainless-steel valve design, the liquid is gently poured onto the side of the bottle, minimizing product agitation, while the level of the product in the bottle remains the same throughout the bottling process — without the need of a levelling unit. Its integrated CIP system with dummy bottle inserts allows for fast and thorough cleaning of all the components in contact with the product. A spray ball in the filler tank makes it easy to rinse the product from the tank after the bottling operation, or when changing the product, be it oil, vinegar, brine, syrup, sauce, wine or liquor.

- Through vacuum-operated filling, the product is bottled in a most natural way, allowing it to maintain its original quality and features

- The filling process is performed without any contact between the product and pumps or mechanical components

- User-friendly, easy to clean and maintain

Filling operation

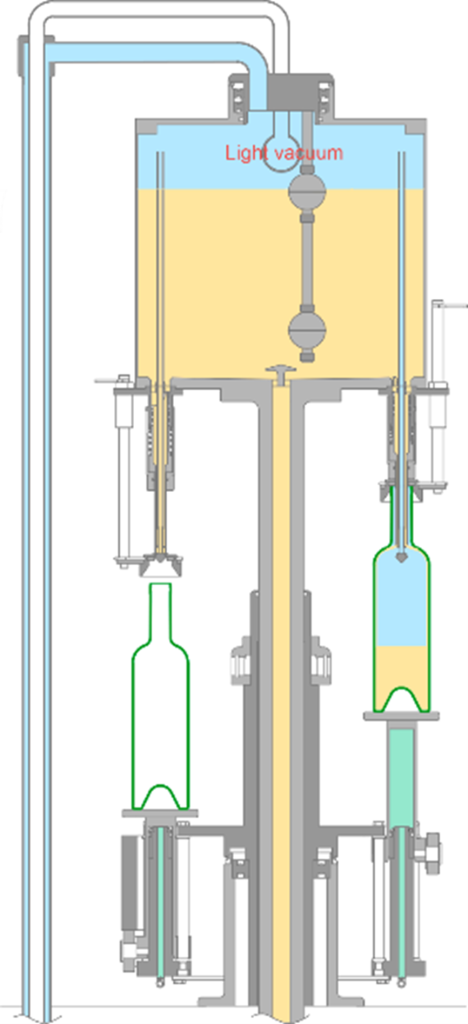

The bottle is transported to the filling position of the filler turret consisting of pneumatic bottle-lifting pistons and a gravity-filling valve. The piston lifts the bottle and opens the filling valve by pressing the bottle neck against a rubber seat on the valve to create a closed, sealed system. Light vacuum in the filler tank will pull the air out of the bottle and empty the venting tube of the filling valve for a quicker start of the filling process. Once the bottle reaches the pre-set filling level, the piston is lowered and the bottle transported from the turret by a star-wheel.

Cleaning in place (CIP):

Product specifications:

Main features:

- Filler tank in mirror finish for easy cleaning

- Pneumatic bottle-raising pistons operated with air trust and cam return mounted externally for easy cleaning and maintenance

- Low vacuum/depression filling system

- Low vacuum filling valves with filling level adjustment. Made from machined stainless steel AISI304, no welds or threads in contact with the product.

- Electric height adjustment

- Dummy bottle for CIP filler

- Washing ball in the filler tank

- Indicator and temperature sensor in the filler tank

- Liquid level sensors in the filler tank for pump control

Options

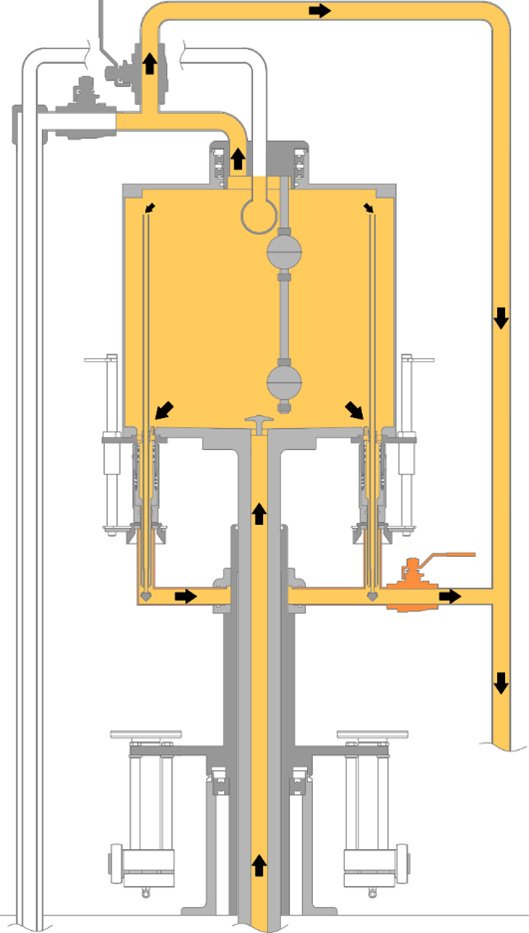

- Light nitrogen pressure in the filler tank

- Centralized filling level control system

- Automatic product return system on the filler with inlet temperature control

- “Neck gripper” system: a set of neck-handling pincers for PET bottles

- Insulated filler tank

- AISI 316 stainless-steel parts in contact with the product