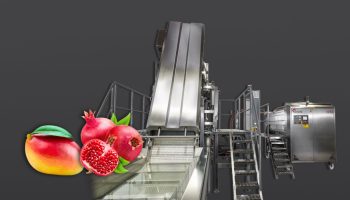

A06 Washer – Elevator – Mill JTM

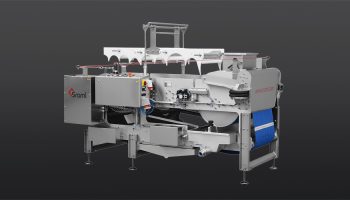

The washer–elevator–mill unit, featuring 3 machines in one, is the perfect alternative to the SRAML standard washer JP, conveyor JT, mill JM and mash pump line when there is little space for production available.

The washbasin, belt elevator and mill of the JTM series are a winning combination, enabling a smooth and efficient preparation of fruits for pressing.

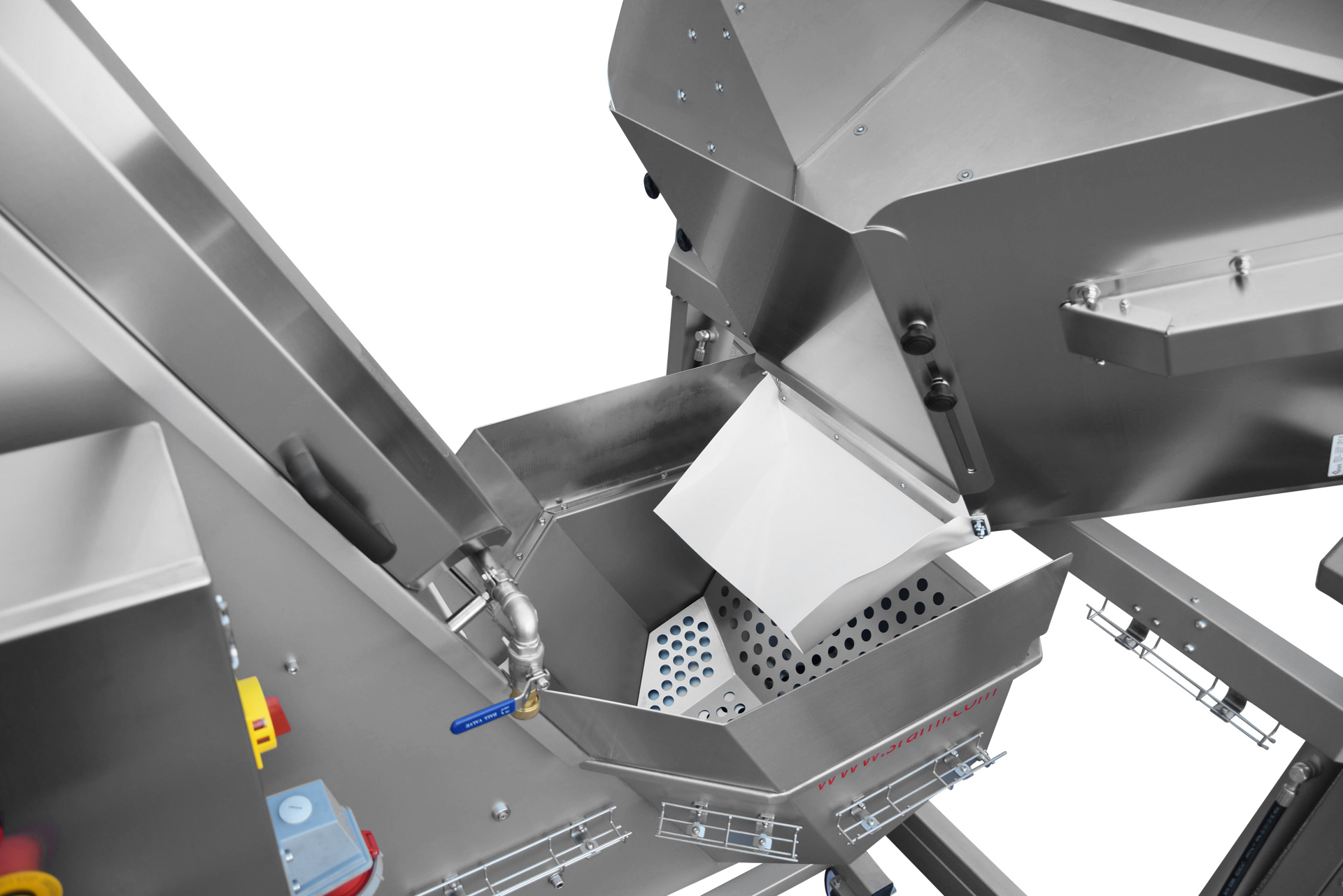

Once the apples are submerged in the water and washed, the elevator belt pushers transport them to the mill. During the transportation, the fruit is rinsed with fresh water by a series of spraying nozzles. The mill with the same characteristics as the JM mill is fitted above the belt press hopper, allowing the mash to be fed directly to the press after being ground, so no pump is needed.

Advantages, compared to the SRAML standard line:

- Less floor space needed

- No mash pump needed

- Lower cost

Disadvantages, compared to the SRAML standard line:

- Less effective washing

- Fruit cannot be inspected after washing

- Mill is placed at height, difficult washing

- Only compatible with belt press

Product specifications

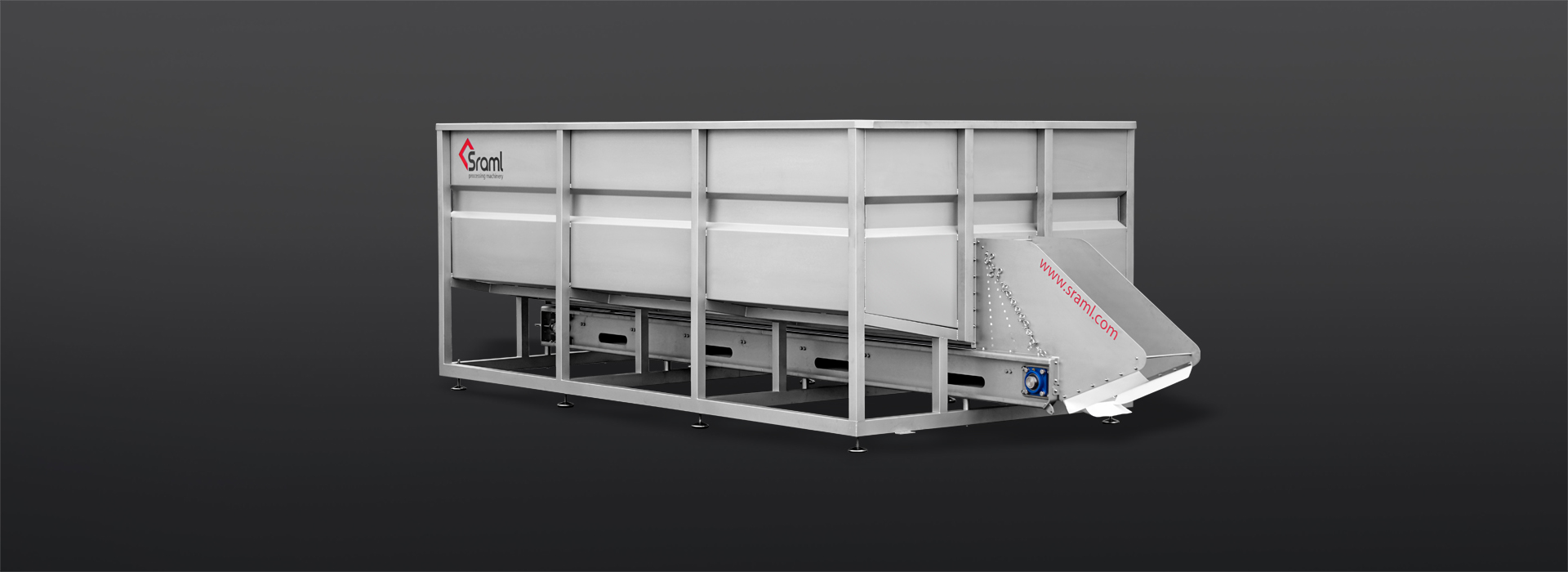

- Stainless steel construction mounted on swivel casters

- Washbasin with wastewater overflow and water discharging valve

- Inclined perforated belt with pushers

- Water spraying system rinses the fruit during its transportation to the mill

- Geared motor drive of the elevator belt with protective cover

- Mill with replaceable grader screen

- Replaceable grader screen available with different hole diameters

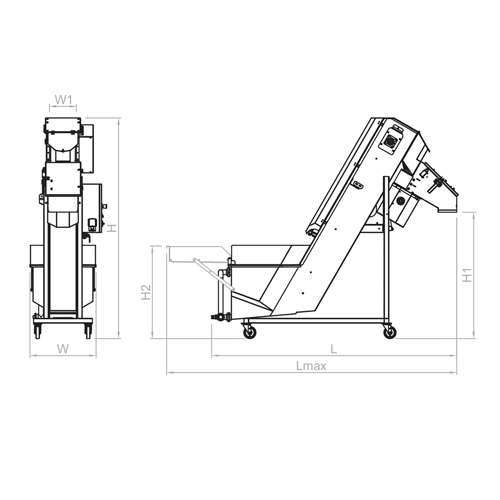

- Conveyor available in different length

- Sorting table on the washbasin

- Dosing gate with a mash sensor on the mill for pack press

- Foldable sorting grid table

- Elevator of different length

- Mill with a more powerful motor

- Different power supply