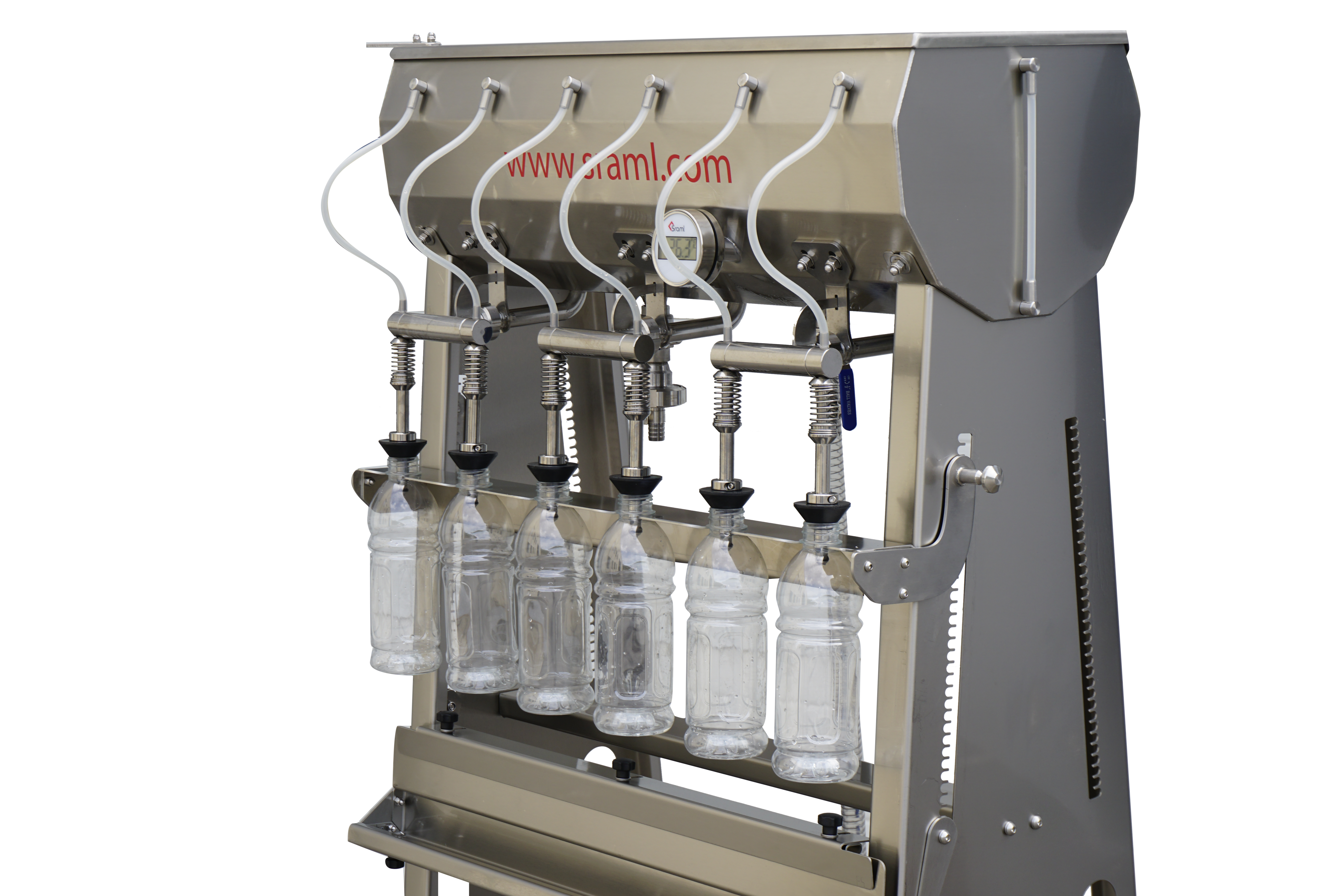

PS Standard line

With a number of upgrades to suit your juice bottling and packaging style, the Sraml PS Standard line of manual bottle filling machines combines the simplicity of design and use with innovative details for the ultimate performance.

Equipped with a set of fine gravity-filling nozzles with adjustable filling level while being flexible enough to allow adjustments to different bottle sizes, the SRAML PS Standard bottle fillers meet the needs of even the most demanding juice producers.

The PS Standard line, equipped with filling valves positioned at the base of the tank, ensures that the tank can be fully evacuated, thereby preventing any wastage of the filling medium.

This user-friendly bottle filling technology greatly facilitates the work needed to fill the bottles and complies with the highest food standards, ensuring top bottling experience and product quality achieved with minimal effort.

Product specifications

- Self-standing stainless steel construction on swivel casters

- Product buffer tank with integrated electrical product level sensor

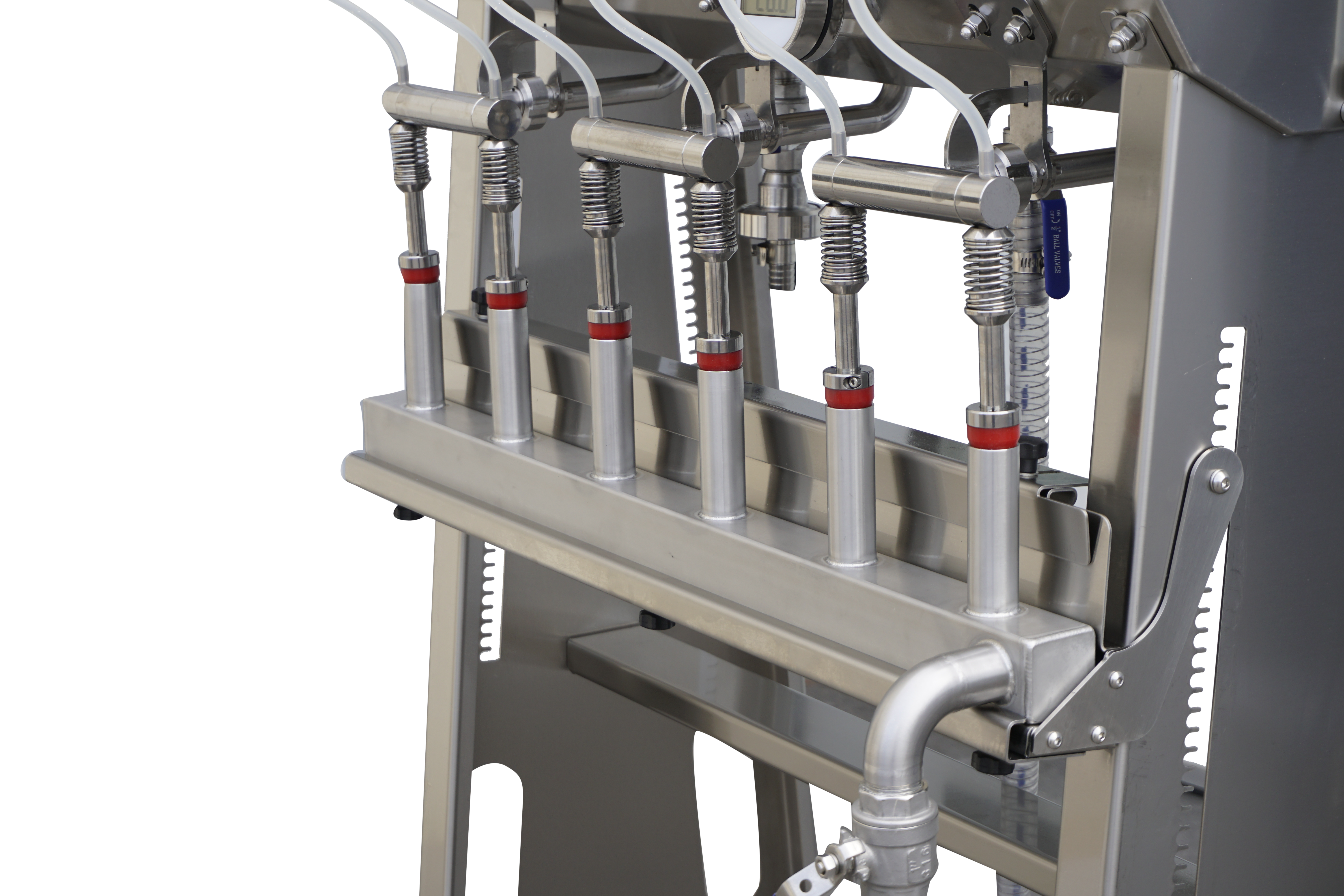

- Set of gravity-filling nozzles with adjustable filling level

- Product temperature indicator

- Bottle rest with adjustments for different bottle sizes

- Product inlet ball valve 1/2″ with connection

- Product drain ball valve 1/2″

- Product level indication on the sides

- Max. bottle diameter: 140 mm

- Bottle height: 50–500 mm

- Filling valve diameter: 15 mm

- Self-standing filler (table version) without swivel casters

- Bottle inertization nozzles — inert gas injection, 2 nozzles

- Dummy bottle (central valve washing nozzle) available with the PS4, PS6 and PS12 model

- Bottle neck supports for plastic bottles available with the PS6 and PS12 model

- PS filler available with integrated feeding impeller pump, electrical cabinet, and automatic feeding by liquid level sensor

- Parts in contact with the product in AISI304 stainless steel

| Name |

|---|

| PS4 (table-top) |

| PS6 (table-top) |

| PS4 (self-standing) |

| PS6 (self-standing) |

| PS12 (self-standing) |

| Length L (mm) | Width W (mm) | Height H (mm) | Hb (mm) | Weight (kg) | Capacity (L/h) | |

|---|---|---|---|---|---|---|

| 450 | 450 | 1000 | 50 - 400 | 35 | 420 | |

| 550 | 450 | 1000 | 50 - 400 | 40 | 650 | |

| 550 / 450 | 600 / 540 | 1700 / 1720 | 50 - 500 | 40 / 50 | 420 | |

| 550 / 550 | 880 / 820 | 1700 / 1720 | 50 - 500 | 50 / 55 | 650 | |

| 550 / 550 | 880 / 820 | 1700 / 1720 | 50 - 500 | 65 / 60 | 1300 |